Product Description

Air leakage test machine tests all types of automotive and industrial parts. It has special tools to seal parts and then injects compressed air into the interior of the parts, detecting changes in pressure to determine whether the parts have leaks.

This machine integrates automated industrial design and sealing testing and has an intelligent monitoring system. It prints a unique test number for each part tested, which is used for quality monitoring and traceability.

Air leakage test machine features

- Highly efficient production efficiency.

We can design automation tools for each industrial part that needs improving production efficiency, or producing multiple workpieces simultaneously to meet your demand for fast delivery. In combination with robotic arms, we can realize an unmanned production mode.

- High-quality industrial design.

The machine’s frame is making of aluminum alloy, and the surface of the aluminum is an Oxidation treatment. The door panel is made of 2mm carbon steel and has a paint surface. The surface of the tool parts is treated with nickel plating, so the machine’s appearance and design are beautiful and in keeping with modern industrial design.

- Wide range of application scenarios.

This air leakage test machine has many applications, including automotive engine parts, air conditioning system parts, household appliances, and aerospace parts. By customizing different tools, we can test many products.

- Precise testing capabilities.

The sensor for detecting pressure is from a well-known brand in China, which uses a manufacturing technology of 14 nanometers. It can judge the slightest changes in pressure in a very short time, making it one of the most advanced sensors currently available.

Air leakage test machine Technical Parameters

| ITEM | DATA |

| Test pressure: | 0.4-0.6mpa |

| Power: | 220V±10% |

| CUP | 32bit 4 cores |

| Refresh rate: | 20Hz |

| Parameter channel: | 100 groups |

| Display accuracy: | 0.1kpa |

| Vacuum test: | Optional |

| Automation | Optional |

| Working environment: | 5-40℃ |

Testing method

This Air leakage test machine seals the parts to be tested, filling them with compressed air.

The pressure sensor maintains the state of detecting internal pressure changes to determine the sealing performance of the parts. This is the positive pressure mode. In the negative pressure mode, the inside is the vacuum to maintain negative pressure and determine whether the parts have leaks.

During the parts’ holding time, two high-precision pressure sensors inside the machine monitor the pressure difference between the tested parts’ outlets and inlets. This is currently the most advanced measurement method.

Optionally available features

- Vacuum pressure test.

- Link intelligent printer.

- Mechanical hand handling.

- Multiple workstation testing.

- Helium test device.

- Automation Drive

- High-pressure test.

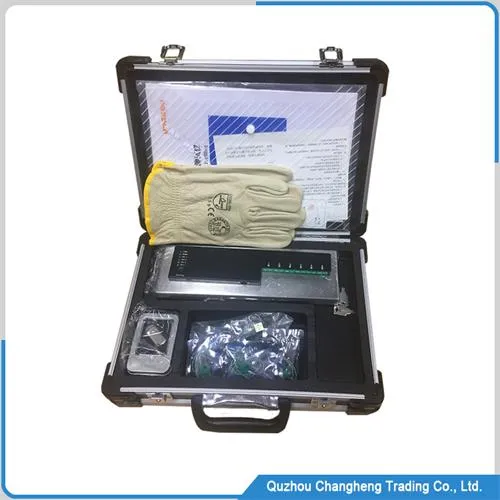

- Laboratory general tools.

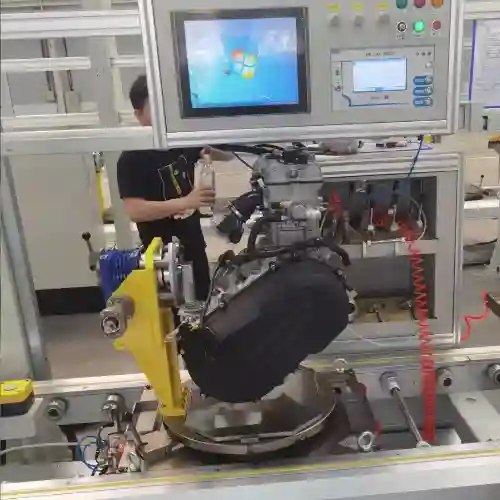

Air leakage test machine working video

This video is just an example. We can customize test tools and design services to meet your product’s needs. If you’re looking for a leak test machine, you can contact us to get the latest details, and we’ll provide the most suitable testing solution for you.

wechat

wechat