Product Introduction

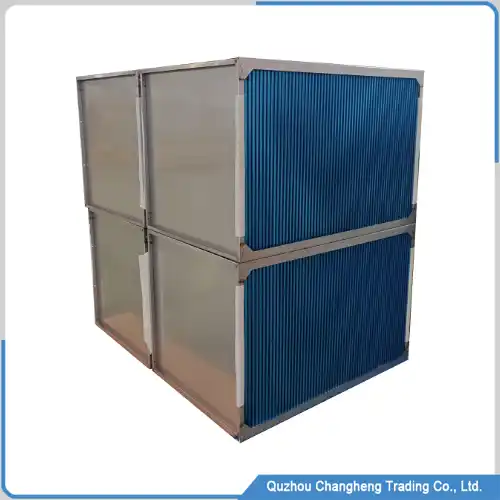

The air to air heat exchanger is an accessory of the ventilation device, It is formed by pressing hydrophilic aluminum foil.

These aluminum foils are cross-stack, And seal the edge of the aluminum foil by bending twice, To form a cube and install it in the middle of the ventilation device,

When the ventilation device is working normally, efficient heat exchange occurs in the respective channels of the cold and hot air heat exchangers, delivering fresh air indoors and saving a lot of energy waste

The production process of air-to-air heat exchanger

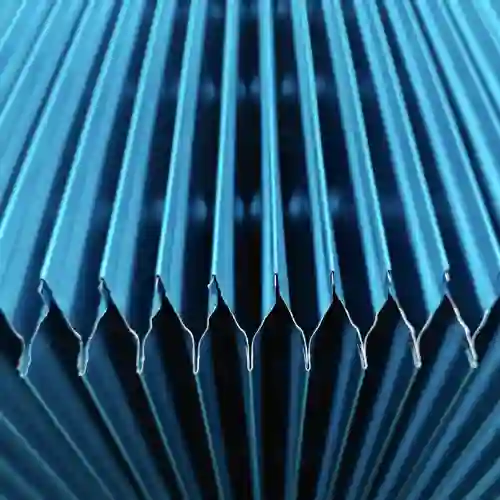

1, Automatic machine pressing of aluminum material for forming, Then cut according to the size. This production process is usually fully automated.

2, Cross-stack the pressed aluminum plates and use specialized tools to bend and flatten the edges of the two aluminum plates. Usually, it takes two bending and flattening steps to achieve a good sealing effect.

Assemble the core of the air-to-air heat exchanger into a cube using this method.

3, Install steel plates and frames onto the cube of the heat exchanger to maintain its overall stability. The middle of the four pillars needs to be sealed with glass glue.

4, After the assembled heat exchanger core is inspected for appearance quality to ensure that there are no quality issues, it can be packaged and delivered to the customer.

You can check the video below to learn how to make this heat exchanger

air to air heat exchanger Technical Parameter

| ITEM | DATA |

| plate material | clearwater alu foil stainless steel 304 ordinary alu foil high-strength plastic |

| plate size | Airflow mode: |

| Service life | 5-8 years |

| Airflow mode | 240 ℃ |

| Airflow mode | cross flow |

| Heat exchange efficiency | customized |

| Fin spacing | 2.5-12mm |

| Packaging | Wood frame |

Our services

- Design the only air-to-air heat exchanger service for you

- Design heat exchangers of all sizes

- Customize all types of air-to-air heat exchangers

- Marine transportation services

- Customize packaging according to your brand

- Far superior after-sales service to competitors

- Consultation services for other heat exchangers

- Build a heat exchanger factory for you

air-to-air heat exchanger factory video

Q & A

A: We can provide both.

A: The height and size of the channels in the heat exchanger are different, and the thickness of the aluminum foil varies. The thickness of the 2.5-7mm aluminum foil is 0.15mm, and the thickness of the 8-12mm aluminum foil is 0.22mm.

A: Its frame material is stainless steel, and some customers choose aluminum alloy.

wechat

wechat