Fin press machine features

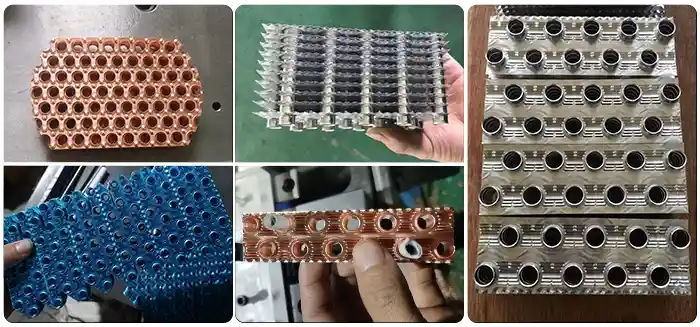

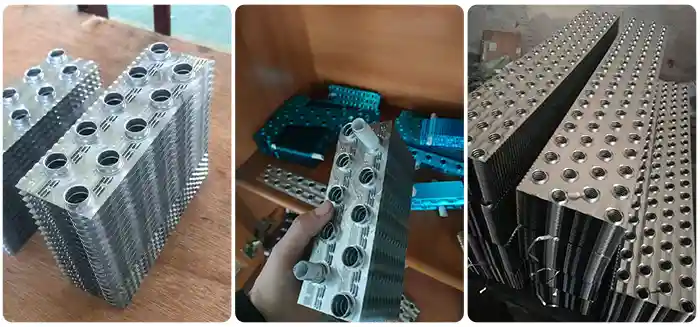

The aluminum fin press machine manufacturer It’s from China, this equipment is the high-speed production line of air conditioning fins is a special production line for fins production in the refrigeration industry; it is composed of an uncoiler, an oil tank, an open high-speed precision press, vacuum sucker, and aggregate device;

PLC electric centralized control system, encoder, Preset chip counting, chip counting, aggregate counting, and single and double jump functions to meet the requirements of a high-speed production line. The main machine has hydraulic overload protection and an electric adjustment device for mold height. The thin oil automatic circulating lubrication system has an oil circuit alarm function.

Aluminum fin press machine data

| No. | ITEM | DATA |

| 1 | Nominal force | 45T |

| 2 | Stroke | 25/30/35/40 |

| 3 | Number of strokes | 200-800 S.P.M 200-700 S.P.M 200-600 S.P.M 200-500 S.P.M |

| 4 | Closing height | 213-243 mm 210-240 mm 208-238 mm 205-235 mm |

| 5 | Slider area | 420*320mm |

| 6 | Adjustment amount | 30mm |

| 7 | Main motor | 7.5HP |

| 8 | Total weight | 4.8 tons |

| 9 | Blanking hole | 100*400 mm 100*500 mm |

| 10 | Fixed-point stop | standard |

| 11 | Clutch and brake | Air & Friction |

Aluminum fin press machine maintenance

- Clean the center column and sliding block guide column frequently, and keep the mold base plate free of dirt when erecting the mold to ensure that the platform is clean and to avoid scratches.

- Add grease to the flywheel (including the feeder) when the new machine has been used for one month. If there is no oil for a long time, it will cause internal wear on the flywheel and affect the performance of the machine tool.

- Replacement of machine circulating oil: the new machine shall be replaced once within one month and then every six months to ensure the regular operation and precision of the machine tool (32 # machine oil or Mobil 1405 #)

Fin production line working video

Q & A

A: This machine has a 45-ton punching force and can produce 300 times per minute.

A: We are an aluminum fin press machine manufacturer; we provide all technical support

A: The packaging of this machine is a wooden crate. We pack the machines lying down to easily load them into containers.

wechat

wechat