Product Description

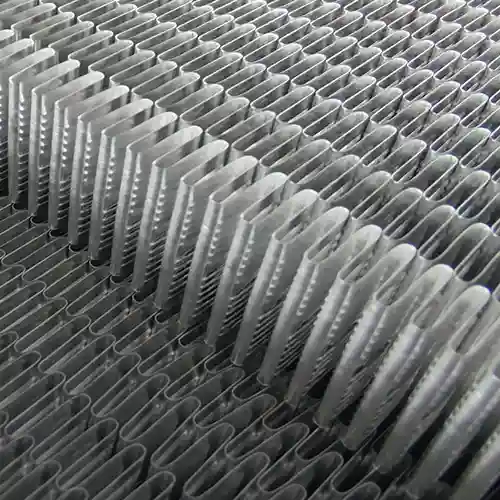

This fin forming machine is key for producing car radiators, condensers, and intercoolers. It mainly involves rolling and forming with rollers,

This device can produce aluminum and copper foil materials approximately 0.06-0.15m thick.

Its roller mold is independently designed and can quickly be replaced to produce different types of fins, but it is not as good as louver, wave, linear, etc.

Fin forming machine technical data

| NAME | DATA |

| Overall dimension | 4650*750*1750mm |

| Foil material | aluminum copper |

| Motor power | 2.2kw |

| Production speed | 0-120M |

| Cutting speed | 60 times/min |

| Power supply | 380V/50Hz |

| Packing | Wooden box |

Fin Froming machine advantage

1. The fin-cutting device operates independently and is driven by a servo motor to control the length of each fin accurately

2. The roller mold of this machine can be combined with multiple sizes, which can save a lot of costs

3. The fin forming machine has an independent lubricating oil device, which will automatically sound an alarm when there is a lack of lubricating oil

4. All controls are complete on a 7-inch touchscreen, allowing engineers to set parameters such as fin length and production quantity. When it meets the production capacity, the machine will automatically stop

5. The fin machine has a 2.2kw motor-driven roller; the fastest production speed per minute is 120m. This high-speed production can meet the needs of the vast majority of users

Raw materials for the fin machine roller

| Name | Materials |

| Frame | C45 steel |

| Partition | Cr12MoV |

| Forming roller | SKH11 |

| Rolling roller | W6Mo5Cr4V2 |

| Bearing brand | SKF |

| Locating pin | SKH51 |

Fin froming machine working video

Other more fin machines

Fin punching machine of Heat exchanger and oil cooler

Machine Overview The Fin punching machine is one of the key pieces of equipment for manufacturing heat exchangers, oil coolers, and intercoolers. The fin stamping machine is mainly used for manufacturing fins in metal foil…

Fin roller machine | condenser fin machine

Machine Overview the radiator fin roller machine is the key machine for processing condensers, radiators, and intercoolers; its total power is 3.5kw. The fin roller mold is made with high precision. The servo motor counting…

Fin progressive die of heat exchanger

Mold Overview 1. This fin Progressive die is suitable for automobile radiators, household air conditioners, central air conditioners, dehumidifiers, etc. 2. It is suitable for aluminum foil with different states and thicknesses at home and…

Condenser fin mold and Progressive die

Product Introduction The condenser fin mold is a tool for continuous high-speed production. It is a fully auto progressive mold tool that combines multiple molds with different functions. This mold is the main production tool…

Support and Services

We provide wooden box packaging that meets international logistics standards for this machine,

It is a plastic bag that contains many desiccants to prevent moisture regain and rust.

Door-to-door logistics service, no matter which country your steel is in, we will deliver the machines to your factory

A 12-month warranty policy and provision of vulnerable parts, allowing users to use this machine generally for 3-5 years

If our engineers need to provide on-site installation and training services, users only need to pay for the engineer’s airfare and hotel.

After the fin forming machine is completed, it will be tested in the Chinese factory, and we can provide users with fin samples to check all sizes.

Q & A

A: Yes, this machine can produce aluminum and copper materials, and the thickness of the foil is 0.05-0.18mm.

A: A machine requires one worker, and we have an automatic feeding machine that can achieve fully automatic production with fin machines. You can contact our engineers for more details.

A: Our machine produces fins with a maximum error of ±0.02mm in height and size.

wechat

wechat