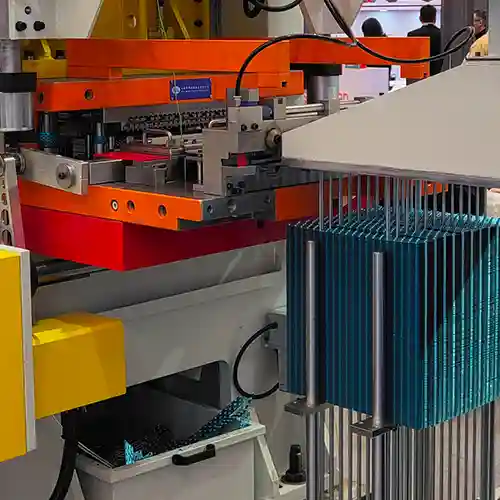

Production line synopsis

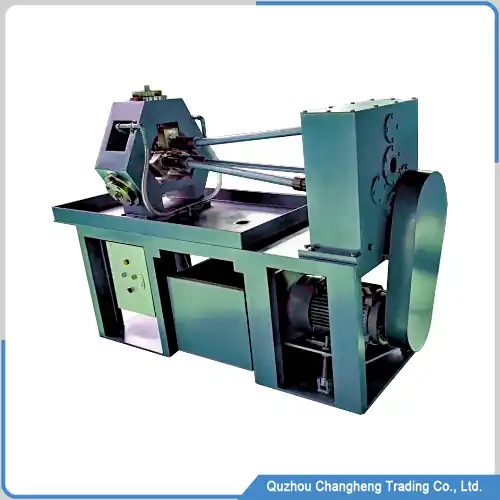

The aluminum fin press is a pneumatic press. The pneumatic press can be divided into open type and closed type, which can be divided into single point and multi-point. The main tonnage range is 25-350. The machine can be customized according to customer requirements

Aluminum fin press production line characteristics

- The body is weld with steel plates, with solid materials and good rigidity;

- High-precision machining is useing, with high parallelism and verticality.

- The guide rail adopts a rectangular, six-sided, extended type, which is matched with the lining plate to improve the stamping accuracy and wear resistance;

- Forced lubrication system is adopted to prevent wear;

- When equipped with grating, it can be stopped in full stroke, and inching can be realized, and it is safer to use at the same time;

- The combined pneumatic friction clutch brake ensures smooth engagement and sensitive action.

- Most models are equipped with electric mold adjustment, and the mold height digital display is more convenient!

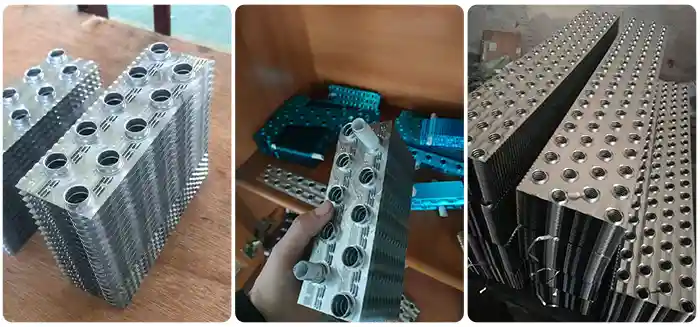

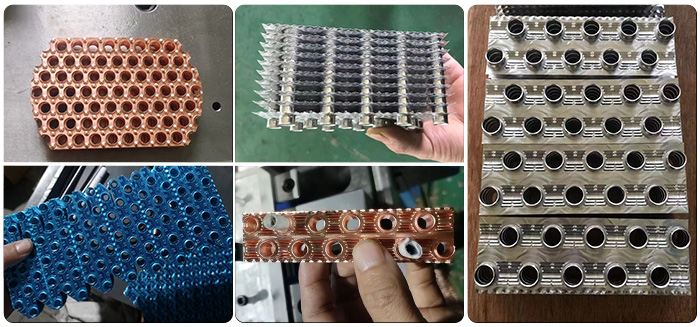

Advantages of production line

Why choose our production line

Our services

Q & A

Q: What is the package of this machine?

A: This machine packs wooden cases. To put containers easily, we will use horizontal packing machines

Q: Does this machine have a manipulator?

A: Our machine has no manipulator; it is a fully customized production line

Q: What is the delivery time for this machine?

A: Because this is a customized machine, our delivery time is 60 days

wechat

wechat