Machine outline

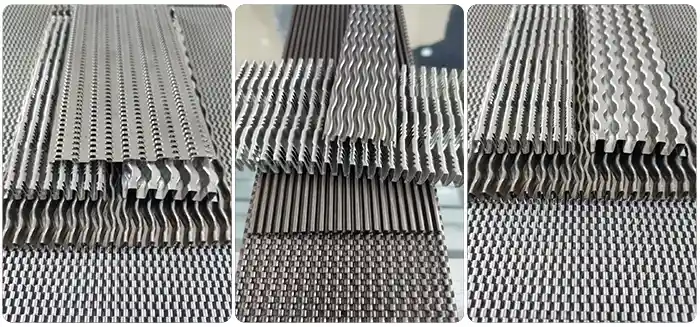

The Flat fin machine produces cooling fins for plate and bar heat exchangers. This equipment is similar to the piston’s working type and continuously produces work up and down. The sliding bushing has an automatic lubrication device. The excess lubricating oil will automatically flow to the oil sump.

This machine is a complete production line consisting of a raw material feeder, a raw material lubrication device, a flat fin molding die, an automatic cutting machine, etc. Among them, the cutting machine is by a servo motor, which can accurately control the length of each fin, and the error will not exceed 0.5mm.

The machine’s appearance is painted using baking, and the color will not change or fade over long-term use. It meets the standards for use in modern factories. We accept customized colors for the machine, providing users with personalized options.

Machine delivery list

Flat Fin Machine Main features

1, The column bushing of the flat fin machine is made of high-speed steel. Its service life far exceeds that of its competitors

2, The mold slider of the fin machine adopts a rolling ball structure, which has a longer service life.

3, The fin machine’s pressing force and production speed should be highly matched with the cutting speed.

4, The touch screen of this machine can directly set production parameters.

5, The Decoiler has an automatic induction switch that controls the uncoiling speed of the aluminum coil.

6, The fin stamping machine has added a limit device. Replacing the mold allows for quick reading and positioning

Flat Fin Machine working video

Q & A

A: The delivery time is approximately 60-65 days.

A: Yes, we have a CE certificate for this fin machine

A: No problem, you can choose any color machine

wechat

wechat