Description

In modern aluminum radiator factories, many machines are required because the properties of engine radiator parts are different. It involves equipment of different types and processes to produce each part and then assemble and test them,

As is well known, producing aluminum radiators is a tedious process, and each process requires effective production control and quality inspection.

This article mainly introduces a new radiator factory with the smallest unit and describes the machines and technical reserves it needs.

Stamping production workshop

This workshop mainly produces aluminum radiators’ head and side plates. A factory with the smallest radiator unit requires stamping machines of different specifications and an ultrasonic cleaning machine.

Machine List

- Stamping machine: 200 tons 1 unit

- Stamping machine: 160 tons 1 unit

- Stamping machine: 45 tons 1 unit

- Mold: many

- Ultrasonic cleaning machine: 1 unit

- Aluminum plate cutting machine: 1 unit

- Sewage treatment equipment: 1 unit

Introduction to Machine Applications

160 and 200-ton stamping machines are uses to produce radiator head plates. Considering that the factory can produce truck-type radiators in the future, the factory needs to reserve sufficient strength for stamping machines to produce large-sized parts

The stamping machines of 45 and 160 tons are used to produce the side panels of aluminum radiators, and these two machines can produce almost all the side plate parts of radiators on the market

The mold is customized for each radiator, and there are usually many stamping molds in radiator factories in China. We recommend choosing the best-selling car model radiator manufacturing mold in the initial stage,

Aluminum plate cutting machine, its function is to cut 1.5 * 2-meter aluminum plates into small sizes so that it can adapt to the average production of stamping molds

Lubricating oil must be applied during the stamping process of radiator parts to protect the durability of the mold and prevent parts from wearing out, so an ultrasonic cleaning machine is needed to clean it.

The regular operation of ultrasonic cleaning machines requires the addition of some chemicals. In some countries, environmental protection is very strict, and all radiator factories require a small sewage filtration device to clean the sewage discharged by ultrasonic machines.

Video of production in stamping workshop

Injection molding workshop of radiator factory

This workshop produces all plastic parts for radiators, such as plastic tanks, external frames for radiators, inlet and outlet ports, dust covers, and other components.

At the same time, this workshop can also produce additional parts for radiators, such as fan frames, fan spiral blades, etc.

Machine List

- Injection molding machine 268-E: 1 unit

- Injection molding machine 320-v: 1 unit

- Injection molding machine 128-e: 1 unit

- Plastic crushing machine: 1 unit

- Injection molding: many

The 320 machine produces plastic tanks of 800mm and other large-sized plastic parts.

The 268 machine produces plastic tanks with a length of 500mm and other medium-sized plastic parts.

The 128 machine is uses to produce small-sized parts,

A plastic crusher is a process of crushing injected plastic waste and reusing it for a second time.

Other machines in the radiator factory

Core assembly workshop of radiator factory

This workshop mainly assembles the aluminum core of the radiator, which requires aluminum tubes, aluminum fins, and many other parts,

This is a crucial task in the radiator’s entire production process. If the fit gap between parts is too large, it will affect the quality of the brazing, and the aluminum core can not be leakage.

Machine List

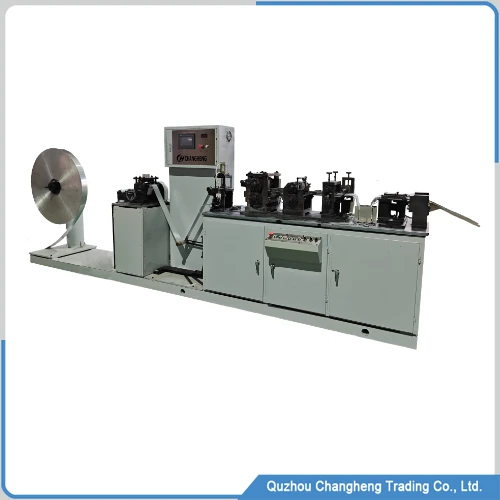

- Core assembly machine

- Fin manufacturing machine

- Aluminum tube manufacturing machine

The fin manufacturing machine is uses to produce cooling fins for radiators. It has two rollers that quickly roll to form aluminum fins into a louver shape,

Rollers can usually be produced in various width sizes, such as 16mm, 36mm, etc.,

By checking the video below, you can learn how to make aluminum fins

An assembly machine is a type of machine that combines all aluminum parts to form a complete core. There are currently many types of such machines, which are not as good as cylinder-driven or servo-motor-driven,

There is a type of core assembly machine that is fully automatic, which is usually product by large OEM radiator factories because it requires a lot of time to replace the model

The smallest unit of the radiator factory, using cylinder-driven equipment, can meet production needs. It can not only adapt to all radiator sizes but also replace models very quickly.

You can check this video to understand the machine’s entire working process.

Aluminum tube manufacturing machines are very expensive, and we do not recommend purchasing one for small factories, so we will not introduce it here.

Brazing furnace

This brazing furnace is a crucial machine for producing car aluminum radiators and the most expensive equipment in the factory. Experienced engineers are required to operate this equipment and ensure the brazing quality of the aluminum core.

Although aluminum brazing technology has been developed for many years, many radiator factories cannot fully master this technology, resulting in scrap aluminum cores in production.

So, it is very important to find an excellent supplier to purchase this brazing furnace and have them provide all the technical support so that the new radiator factory can quickly start this project and smoothly put it into operation, creating economic benefits.

Please watch this video to learn more details about it.

Packaging and testing of radiator factories

This workshop is responsible for installing plastic tank parts for radiators, conducting leak tests on the radiators, and then packaging them,

Machine List

- Plastic Tank Crimping Machine

- Leakage testing machine

- Packaging machine

- Laser labeling machine

Plastic Tank Crimping Machine

The plastic tank installation machine assembles plastic parts and aluminum cores to form a complete heat sink,

A rubber gasket between the core and the plastic parts seals the two parts and prevents the radiator from leaking during everyday use.

This machine can be flexibly uses by simply editing its working steps to adapt to many car radiators, and replacing the model does not require additional costs.

Leakage testing machine

This machine tests radiator leakage. Each radiator must be tested before packaging; otherwise, it will not leave the factory.

A leaking radiator is not acceptable to customers, so the importance of this testing machine is self-evident

Packaging machine

Everyone knows the importance of packaging, and of course, radiators are no exception. A good packaging can greatly increase the value of your product,

So what kind of packaging machine do you choose for your radiator factory? This is a very important choice

Laser labeling machine

This machine is not a necessary equipment for producing radiators, but some radiators require engraved codes or logos to identify their traceability or increase brand influence.

The following video shows the production steps of the entire radiator. You only need to watch this video to know how to produce a complete radiator

wechat

wechat