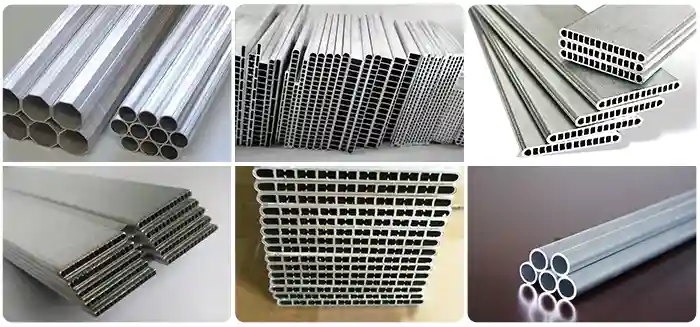

aluminum tube mill production

1. Considering the transportation cost, the proportion of internal and external ore may be adjusted for ore preparation, and the proportion of internal ore will increase.

2. In order to ensure the profit of aluminum pipe and reduce the cost, change the price with quantity, reduce the output pressure and reduce the output, so as to reduce the total ore consumption.

3. High-frequency welded aluminum tubes without advantages in short process and geographical location may be forced to reduce production due to losses caused by increased raw material warehousing and sales costs.

Aluminum tube transport

1. The trading habits of high-frequency welded aluminum pipes have changed, the number of factories mentioned has decreased,

The number of warehouses mentioned has increased, resources have been transferred from the factory and warehouse to social inventory, and the role of the market reservoir is more prominent.

2. In the short term, transportation costs are expected to increase by 30-50%. Because the current cost-bearing entity is not confirmed,

The transportation forms a vacuum, resulting in a shortage of short-term transportation capacity, an increase in the arrival cycle, and a decrease in the short-term transaction volume.

3. Adjust the transportation mode of high-frequency welded aluminum pipe and aluminum ingot, reduce automobile transportation, and increase fire and water transportation.

Aluminum tube clean

1. Use a soft cloth soaked with water-diluted detergent to quietly wipe the board surface;

2. Then wash the board surface with a lot of clean water to wash away the dirt;

3. Check the board surface and clean it with detergent if it is not cleaned locally;

4. First, wash the surface of the board with a lot of clean water;

5. Wash the board surface with clean water until all the detergent is washed away.

Note: do not clean the hot aluminum tube (when the temperature exceeds 40 ° C), because the rapid evaporation of water is harmful to the baking paint on the surface of the aluminum tube!

Special attention should be paid to the selection of a suitable aluminum tube detergent. A fundamental principle is that neutral detergent must be selected! Please do not use strong alkaline detergents such as potassium hydroxide,

sodium hydroxide or sodium carbonate, strong acidic detergents, abrasive detergents, and paint-baking soluble detergents

Maintenance of high-frequency welded aluminum tube mill

1. In the process of use, we must strictly operate according to the operation process in the operation manual, let alone overload the operation and use of the tube mill machine. In addition, before complaining about production, that is, mechanical operation, we must check whether all parts of the machine can work normally and whether there are any faults, Only when all parts and indexes of the machine are normal can it be started and put into production, otherwise it will cause loss to the machine.

2. After checking all parts of the high-frequency welded tube unit, we can start the machine for operation. During the machine’s production process, we must ensure its temperature and production status stability. If the machine fails, we must stop production in time and check what parts of the machine have problems, so as to avoid greater losses. The main faults include unstable mechanical operation, grinding of the machine, and abnormal noise during operation. If there is a problem, it should be checked in time.

3. After the aluminum tube mill has been used for a period of time, we should pay attention to regular lubrication and cleaning of the machine to ensure that the aluminum tube mill is clean. Only in this way can the machine usually operate and be light in use. The aging parts in the machine must be replaced in time to ensure that the tube mill machine can operate normally at any time. In addition, when the machine is not applicable, take good care of the high-frequency welded pipe unit, and do not discard it arbitrarily.

For more details about the aluminum tube mill, please get in touch with us

wechat

wechat