Machine Overview

Vacuum oven is a widely used name for ovens with a vacuum environment, which are used in various industrial fields such as aluminum brazing, metal purity extraction, metal softening and hardening, and passivation of metal parts in aerospace

Some research companies also require these vacuum ovens for the study of rare metals, as the vacuum environment and high temperature are very beneficial for changing the properties of metals

Vacuum oven list

The purpose of a vacuum oven

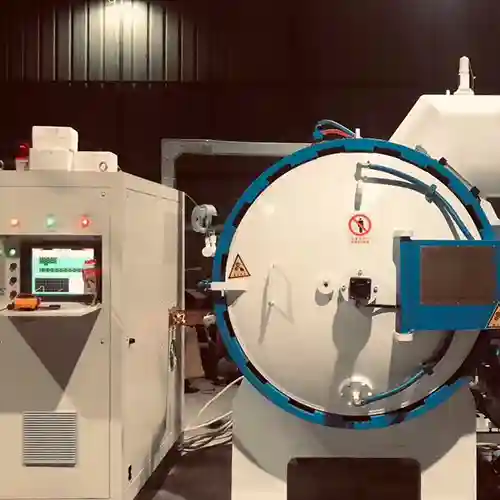

vacuum quenching furnace

This vacuum quenching furnace is hardening metals. In some special fields, metals require hardening treatment, such as molds, key parts of machines, etc,

Usually, Oil quenching and gas quenching are two types of metal hardening, both of which aim to make the metal harder, but there are some differences in the process

vacuum braze furnace

This vacuum oven welds multiple metals together at high temperatures. The advantage of welding in a vacuum environment is that the temperature is precisely controlled and the welding is firm

Usually, Vacuum welding high-end parts due to high welding cost, such as aerospace parts, some military parts, etc

Advantages of Vacuum Oven

Let’s take the vacuum brazing furnace as an example to understand its advantages

1, The programmable control system, which means that users can edit a set of production steps that meet the temperature and vacuum pressure requirements according to the production process

2, The vacuum is a horizontal structure, and it is easy to load parts into the chamber or remove them using a dedicated forklift

3, The latest vacuum pump meets the strictest environmental requirements,

4, There is a cooling water circulation inside the furnace body, which not only maintains a low temperature for the furnace body but also quickly cools the inside of the furnace body

Technical data of vacuum furnace

| ITEM | DATA |

| max temperature | 1350℃ |

| Insulation | 5-layer SS304 |

| Heating | Molybdenum metal |

| Chamber size | customized |

| Type | Horizontal |

| Transformer | including |

| Cooling | Water cooling |

| Nitrogen protection | including |

Vacuum oven manufacturer factory

Other additional machines

wechat

wechat