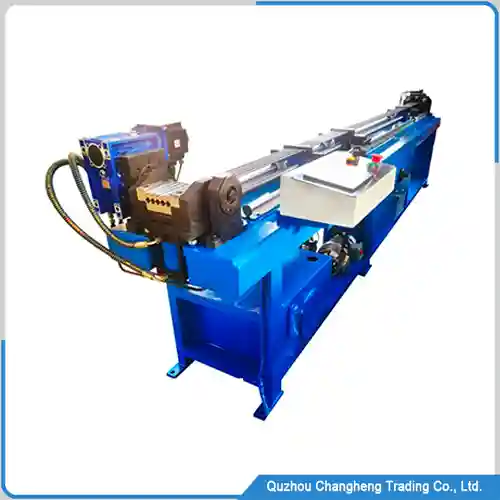

Machine Description

This Panel bending machine is an amazing device that enables complex sheet metal parts to enter fully automated production, saving human resources and increasing production speed by more than threefold. The consistency of the parts being make has been excellent.

This bending machine can write bending programs through industrial computers, and no matter how complex the structure of your sheet metal parts is, it can complete bending work in multiple steps at once

This advanced control system meets all the requirements of modern Industry 4.0, realizing all the requirements of large-scale production, and can also customize special parts for users

Panel bending machine technical specifications

| ITEM | DATA |

| Plate Width | 1450mm |

| Plate Length | 1700mm |

| Bending Length | 1600mm |

| Bending Height | 175mm (300 optional) |

| Material Thickness | AL: 2.5 mm MS: 2.0 mm SS: 1.5 mm |

| bender Angle | 0-180° |

| Opening Height | 180mm |

| Bending Speed | 0.5s / press |

| Min Radius | 1.2mm |

| Min Forming Size | Four sides 300*200mm |

| Min Forming Size | One side 200mm |

Panel bending machine control system

The control system of this machine is an important part, centralized in one console, consisting of a 10.1-inch touch screen and buttons, and reserved with expansion interfaces for connecting other devices to work together.

The touch screen visualizes the 3D view of the bending machine, allowing workers to set bending data based on the size of sheet metal parts. This process is very simple without complex code programming, and new workers can master all the skills in just 2 hours through simple training.

This control system can write bending programs and set production output. When the machine meets the production calculation, it will automatically stop,

It can also set and store different bending data for each sheet metal part. The data can be directly called for the next production of the same part without repeating programming steps.

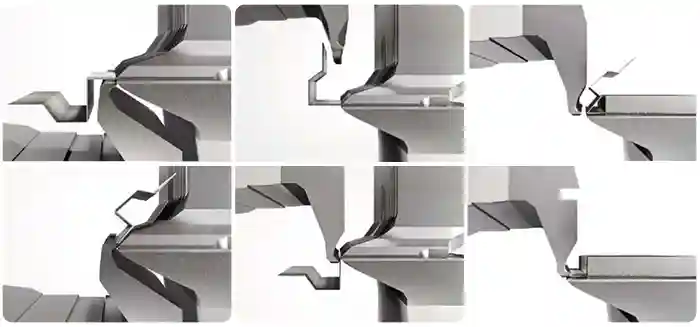

Bend Types

- Straight bending

- Bend downwards bending

- Ruffle bending

- Half circle bending

- Closed bending

- Offset bending

- Right angle bending

- Angle bending

Panel bending machine working video

Machine advantage

1. Workers can quickly use this machine with a friendly control interface and visual operation.

2. Compared to European machines, our equipment is very cost-effective.

3. Complex parts can also be fully automated for production, completing all bending work in one go.

4. It requires only one plate bending machine and can be applied to various metal plates, such as iron, aluminum, copper, stainless steel, etc.

5. Bending tools can be quickly removed, installed, and customized for complex sheet metal parts.

After-sales Services

- The warranty period for this machine is 12 months after installation and debugging ends.

- During the warranty period, free maintenance is provided for any malfunctions that occur during the normal operation of the plate-bending machine.

- During the warranty period, the seller shall bear the cost of repairing or replacing machine parts.

- The seller provides free consumable parts as a gift, and this machine can use smoothly for 3-5 years.

wechat

wechat