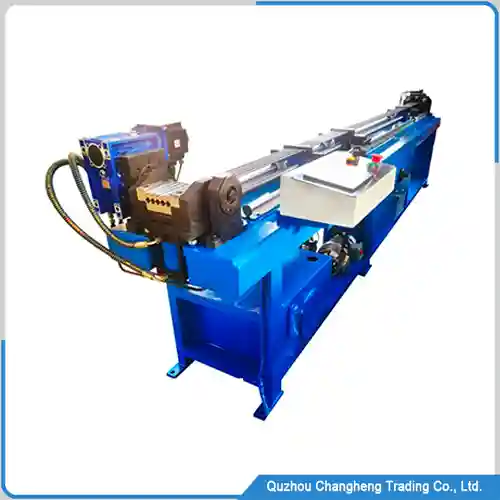

capillary tube bender machine outline

The capillary tube bender machine mainly bends aluminum flat tubes into an S-shape to meet the production needs of condensers and evaporators.

In today’s industrial field, machine automation has become a trend that is widely applied in various industries. In the manufacturing industry, machine automation can not only improve production efficiency but also reduce errors in manual operations

In the production process of coil-type evaporators, aluminum flat tubes require multiple bends to be completed, and this capillary tube bender machine can accurately control the bending radius and length of the aluminum tubes, ensuring that each bend can achieve the desired effect.

At the same time, the capillary tube bending machine can also automate the cutting operation of aluminum pipes, further improving production efficiency.

Technical Parameter

| ITEM | DATA |

| Bending diameter: | customized |

| Bending length: | 20-800mm |

| Pipe thickness: | 1.5-8mm |

| Inner diameter of coil: | 400mm |

| Outer diameter of coil: | 800mm |

| Continuous production: | Yes |

| Automatic shortening: | already included |

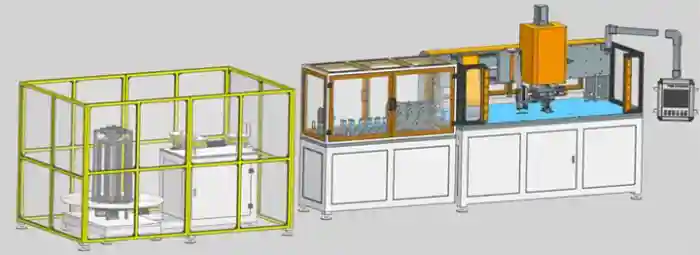

capillary tube bender machine Work steps

Unwinding of aluminum flat tubes

Aluminum tube uncoiling is the process of unrolling the aluminum tube from the coil material for subsequent processing. This work is usually completed by a specialized aluminum tube uncoiler. The uncoiler unfolds the aluminum tube from the coil and sends it to the bending machine for processing.

Straightening up and down

Straightening up and down is an important step to ensure that aluminum pipes do not deform during bending. The capillary tube bender machine has been equipped with upper and lower straightening devices for correcting the straightness and flatness of aluminum pipes.

By straightening up and down, it can be ensured that the aluminum tube will not be subjected to unnecessary pressure during the bending process, thereby ensuring the bending quality.

Straightening Left and right

Left and right straightening is also an important step to ensure the bending quality of aluminum pipes. By aligning left and right, it is ensured that the rotation angle of the aluminum tube during bending is correct, avoiding twisting or deformation of the aluminum tube during the bending process.

transportation

After completing the straightening, the aluminum tube will be transported to the bending position of the equipment, ready for bending processing. Each aluminum tube will be transported according to the required size to ensure the correctness of product dimensions.

capillary tube bender

Bending is the most important step in the entire capillary tube bender machine workflow. When bending, the bending machine applies a certain amount of pressure to the aluminum tube to bend it into the desired shape. This machine has a fully automatic production capacity for continuously bending flat pipes

Cutting aluminum pipes

After completing the bending, the aluminum tube will be automatically cut. Just set the length of the pipe, the entire production process does not require human intervention, and all operations will be fully automated

wechat

wechat