Machine Overview

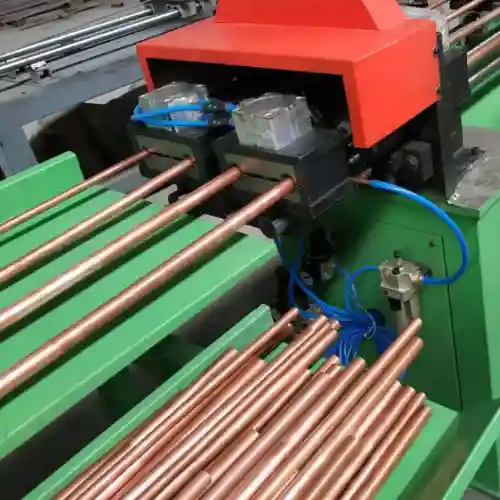

The Tube straightening machine is a production equipment for heat exchangers, which is specifically used for straightening and cutting copper coils. This device has 6 workstations that can independently cut copper pipes of different diameters. In theory, it can cut pipes of any length

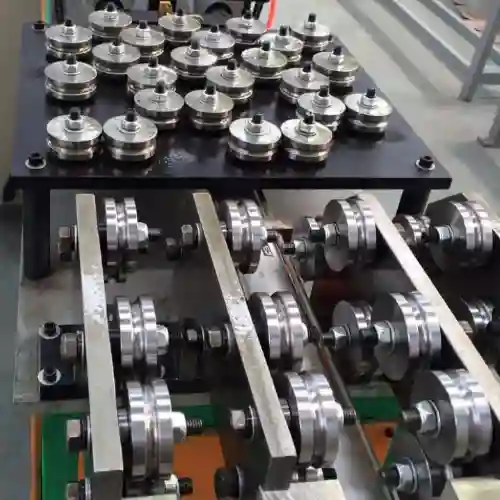

Each channel of the machine has multiple sets of rollers running independently to straighten the copper pipes up, down, left, and right. The cutting device rotates the rollers to cut without any burrs

The cutting length of the pipe is controlled by a servo motor, which drives the screw to move in a straight line and precisely controls the length to maintain good consistency

Tube straightening machine Characteristics

- Multiple workstations and multiple sizes

We accept customized 4-8 or more workstations, each of which can independently produce different pipe diameters and lengths.

- Servo motor drive

With the development and progress of industry, the application of servo motors is becoming more and more widespread. This machine also uses servo motors as a control for the length of pipes, providing a guarantee for production consistency.

- Chip-free cutting technology

Due to the special nature of heat exchanger production, the tubes need to be inserted into the holes of the aluminum fins, and the edges of the copper must be kept smooth and free of burrs. Our machine adopts chip-free cutting, which will not have any burrs. Users can use it with confidence.

- Touch screen control

The control panel of the pipe straightening machine is equipped with a touch screen, reducing physical buttons. Users can preset parameters according to their actual production needs, achieving fully automatic production of the equipment.

tube straightening machine Technical Parameter

| ITEM | DATA |

| Control system | PLC touch screen |

| Main drives | servo motor pneumatic |

| Programmable | Yes |

| Pipe material | aluminum copper |

| Pipe diameter | 5-20mm |

| Workstation | 4-8 PCS customized |

| Pipe length | 100-3000mm |

Copper tube production steps

Our copper tube straightening machine has a material rack, Lay the coil tube flat on the rack.

Thread the coil tube through the plastic channel and insert it into the gap between the rollers.

The tool for linear motion will clamp the copper tube and move forward, with the distance set through the touchscreen.

After the machine moves the pipe to the specified length, it performs burr-free cutting.

The cut pipes slide into the material trough, and the production of one pipe ends here.

The machine will repeat these steps to achieve fully automated production without the need for workers to supervise during the process.

wechat

wechat