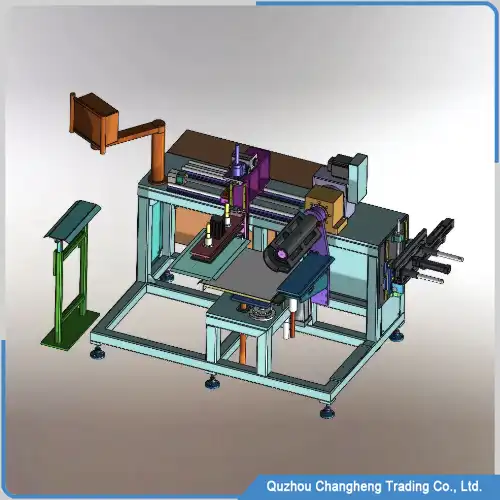

Machine Overview

This condenser coil bender machine is an efficient automated device designed for bending cores in household air conditioning condensers. This machine uses multiple servo motors as power sources and can achieve precise motion control.

By setting the program, the operator can accurately preset the bending angle and length of the condenser core, ensuring that each bending meets the design requirements.

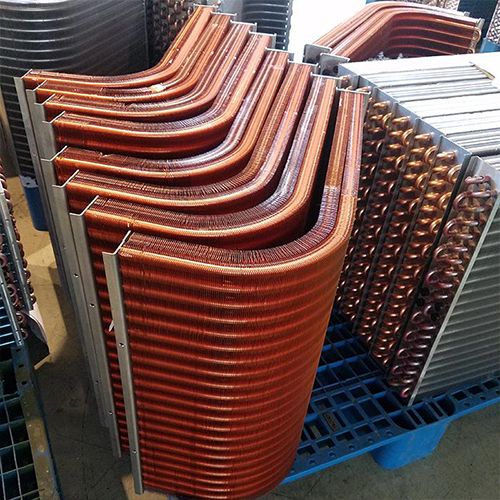

Whether you bender the core into an L type, U type, or G type, the entire bending process does not require manual intervention, and the machine automatically completes it, significantly improving production efficiency and product consistency.

Condenser coil bender data

| No. | ITEM | DATA |

| 1 | Core thickness | 3 layers |

| 2 | Bending angle | 0-120 degrees |

| 3 | Core length | 400-1000mm |

| 4 | Maximum width | 1500mm |

| 5 | Bending drive | motor |

| 6 | Bending type | “L” “U” “G” |

| 7 | Bending radius | R60-100 |

| 8 | Platform control | servo motor |

| 9 | Touch screen | Yes |

| 10 | Language | optional |

Condenser coil bender advantage

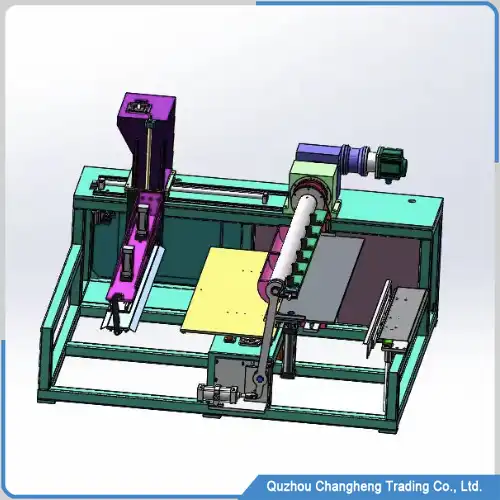

- Highly automated:

The entire bending process requires no manual intervention and is a fully automatic production process. External robots can be uses to improve work efficiency faster.

- High-precision control:

The servo motor controls the movement of the coil core and the bending angle, making the bending angle more accurate.

- Highly safe production:

Since the machine’s working area have a safety barrier, the machine does most of the work, reducing the operator’s exposure to dangerous areas. Thus, the machine’s operation is very safe.

- Good repeatability:

The setting program of the condenser coil bending machine can produce standardized products, ensure product consistency, and maintain stable output quality over the long term.

- High adaptability:

Programming can adjust production parameters, adapt the bending angle and size to different product designs, and achieve the goal of diversified production.

Electronic control operating system

The condenser coil bender machine adopts PLC centralized control, supports manual and automatic operation, and has fault display and automatic counting functions.

The operation panel integrates a touch screen and control buttons. It has an emergency stop button that is identified for easy operation.

The installation of electrical components follows Chinese standards, and the grounding is reliable. The control cabinet adopts plastic comb hole wire slot wiring with precise circuit numbers, clean panels, and clear label fonts. The electrical box is equipped with a fan for cooling.

Condenser coil bender machine working video

Control system of condenser coil bender

Many parts of this machine’s control system come from well-known brands, such as Siemens, Mitsubishi, etc., and the servo motors are from Delta.

The PLC can be programmed logically, allowing operators to input the bending angle and size through the touchscreen, set

different working steps for each part, and realize the ability of automatic production.

The control box internally has reserved IO interfaces, which can be connecte to manipulators to realize the factory’s linkage production capacity and meet Industry 4.0 requirements.

The touchscreen is available in both Chinese and English. We can customize a third language for users, such as Russian, French, Arabic, etc.

wechat

wechat