Machine Overview

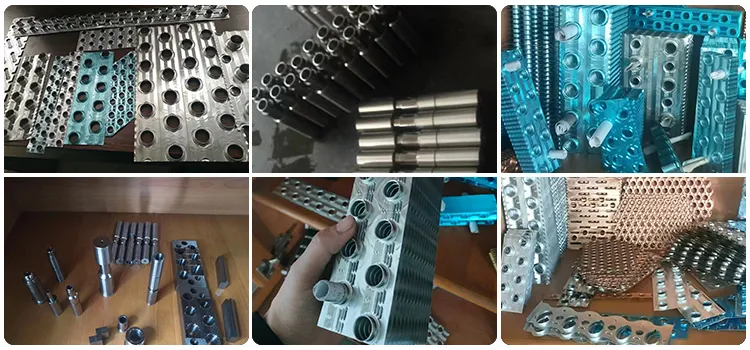

The high-speed fin stamping machine produces heat exchanger and condenser fin parts. It can reach a maximum speed of 280 times per minute, currently the highest level in the stamping machine industry.

This machine adopts a pneumatic drive device with multiple gears to convert stamping force. Compared with traditional stamping machines, it has the advantages of continuous and stable power output and silent production.

The stamping machine slider has vertical guidance and a balancing device to ensure the product’s accuracy and stability during high-speed production.

Fin stamping machine features

1. This stamping machine has multiple lubricating oil tanks, and pressing its handle can add lubricating oil to the stamping machine. This humanized design provides great convenience for equipment maintenance and upkeep.

2. The device has a central control screen that alerts for malfunctions and displays the cause of the problem. Engineers can quickly correct and troubleshoot it.

3. The fin punching machine has undergone design optimization and is one of the professional equipment for producing heat exchangers and condensers. Once you receive this machine, you can produce it usually without additional modifications

4. The fin stamping machine’s pointer, slider distance display, and other display units are all digital display modes that can be connected to the network to meet the production requirements of Industry 4.0.

5. It has multiple working modes, and fully automated production is one of them. This mode does not require worker participation and will automatically stop when the output meets the production demand,

Technical Parameters

| part name | Value |

| Sucking Length | 1000mm |

| Width of Material | 300mm |

| items Model | CH-CY45C |

| Main Motor Power | 5.5kw |

| Speed Adjustment | FDI |

| Capacity | 450 KN |

| Protect Type | Hydraulic |

| Slide of Stroke | 40MM |

Fin stamping machine working video

Installation precautions of fin punching machine

1. This machine is not allowed to be installed on the second floor of the factory; it can only be installed on the first floor with reinforcement on the ground,

A particular sponge layer is at the bottom of the machine to alleviate the vibration caused by stamping.

2. Only volatile oil can be added to the lubricating oil of raw materials, and other lubricating oils may have adverse effects on the mold

3. The fin stamping machine is transported horizontally, and installation requires standing. Engineers must strictly follow the instructions for each step of the operation

4. The theory of this machine is that it can install all types of fin molds, but please note that when replacing molds, the machine must be in disconnected mode, or the power must be turned off

5. We provide free installation services regardless of where your factory is, and you only need to pay our engineers’ travel expenses.

Q & A

A: the weight of this machine is about 6.3 tons

A: Our after-sales service does not intentionally damage the machine. The warranty is one year

A: We will lay the machine flat and pack it in wooden boxes.

wechat

wechat