Product Description

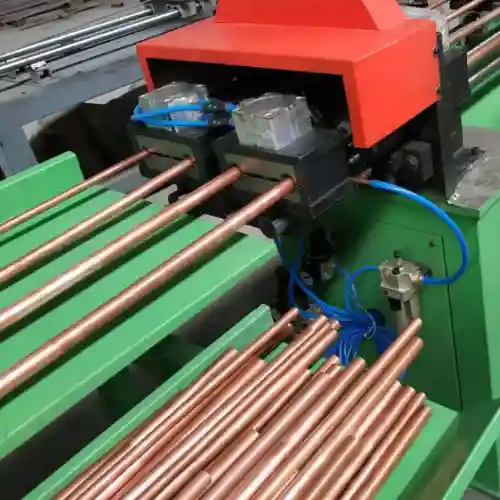

The copper tube cutting machine is one of the important machines in the HVAC industry. It uses a burr-free cutting technology, which is conducive to inserting the tube into the hole of the fin.

From the coil tube to the completion of cutting, the process is one step and does not require manual intervention. The production process is fully automatic

The servo motor controls the movement of the screw, accurately controlling the length of each tube to be cut and maintaining good quality output.

Copper tube cutting machine features

- Multiple workstations

The machine has multiple workstations working simultaneously, which significantly increases production efficiency.

- Precise control

A servo motor controls the movement of the tube and can accurately control its length.

- Multiple size applications

A machine can straighten and cut multiple tube diameters, providing customers with diversified production needs.

- Full automatic production

This copper tube cutting machine can perform tube straightening and burr-free cutting in one step, achieving a fully automated production mode.

- Cutting various metal tubes

This machine can cut various metal tubes, such as copper tubes or aluminum tubes, which is very beneficial for factories.

Technical Parameters

- Drive Type: Servo motor and pneumatic

- Workstation: 4-8pcs optional

- Voltage: 2.5kw

- Power supply: 380v/50Hz (or other Power supply)

- Air pressure: 0.4-0.6mpa

- Tube material: copper or aluminum

- Tube diameter: 3-20mm

- Material properties: Soft state

- Production speed: 10-20 pieces/minute

- Production mode: Unattended

- Control type: PLC and touchscreen

- Language: English and others

- Appearance color: The default is gray and white

- Dimensions: 5*1.2*1.5m

- Machine weight: 800kg

Copper tube cutting machine working video

No-burr cutting technology

In the production process of the HVAC industry, copper tubes need to be inserted into the fins, and then the tubes are expanded to make them tightly combine with the fins. If the tubes have burrs, it will be tough to insert them.

Therefore, burr-free cutting plays an important role, and the cut edges will not have any burrs. This cutting method uses three circular blades that rotate rapidly and squeeze the metal tube, achieving the purpose of cutting.

This cutting method is highly efficient and avoids material waste. Moreover, it doesn’t produce scraps during the cutting process, which is energy-saving and environmentally friendly.

Copper tube cutting machine applications

With technological innovation and development, aluminum and copper tubes are useing in various industries, and there is also an increasing demand for this kind of burr-free cutting machine.

Let’s give a few simple examples.

This machine is needs to cut many parts in the automotive industry, such as the radiator tube, the irregularly curved air conditioning system pipes, and the brake fluid transmission pipes.

Many parts of household appliances need this machine to manufacture, such as the heat exchanger of a refrigerator and the copper pipes inside a water heater etc.

Metal tubes are also extensively useing in the military and shipbuilding industries. This tube-cutting machine is vital production equipment.

This machine is need in many industrial fields. If your factory also needs a cutting machine, don’t hesitate to contact our engineers. We will recommend the most suitable machine for you.

Instructions for using the tube cutting machine

- The length of the tube cut by this machine is unlimited, which means you can cut metal tubes of any length. But you need to place the machine in a workshop with enough space.

- Before you start automated production, you must set the tube length on the touchscreen and save it.

- The exact length must be set for the simultaneous production of multiple tubes of different diameters.

- The feed rack of this copper pipe cutting machine can accommodate two types of coils. It can be placed flat on the ground or hung on a rack.

- Install the coil tube feeder rack, which needs to be reinforced with expansion screws. Enough space should be reserved around it for easy transportation of materials.

wechat

wechat