Purpose of equipment

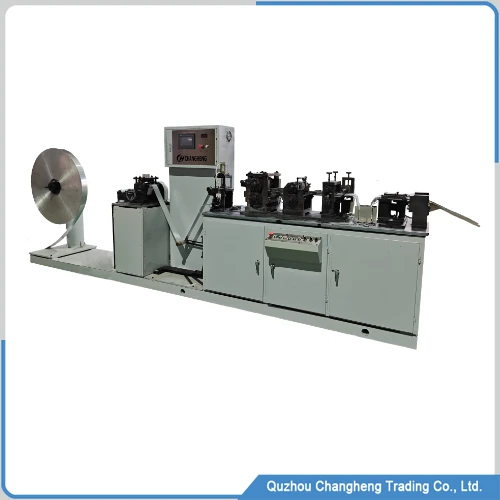

The fully automatic core assembly machine is one of the production equipment for engines and radiators. Multiple servo motors mainly drive it, and the aluminum tube automatically drips. Workers only need to install the fin, and the machine automatically completes the other steps.

By setting the size through the touchscreen, the machine can be compatible with different sizes of radiator aluminum cores, which means one machine can meet 80% of the after-sales market’s radiator needs.

This core assembly machine is scientifically designed and can replace pitch tools at a low cost, enabling the assembly of automotive condensers and intercoolers and meeting the diverse needs of customers.

Main features of Core assembly machine

1. By quickly setting the size of the aluminum core through the touchscreen, we have significantly saved downtime.

2. Servo motors run smoothly, drive the entire machine, and won’t generate noise during production.

3. In the production process, if the machine encounters any program errors, it can be reset to its original state with a single click, thereby eliminating the erroneous program.

4. The surface of the key parts has been treated with nickel plating, which makes them look very beautiful. After long-term use of this machine, the surface of the parts will not rust or oxidize.

5. The electrical control parts and pneumatic accessories are all from internationally renowned brands; users do not need to worry about the machine’s lifespan.

Core assembly machine technical parameter

- Main film spacing range: 380-1200 mm

- Fin width: 16, 18, 20, 24, 26, 32mm

- Fin wave height: 8mm

- Number of flat tubes: maximum 80 (calculated by the spacing of 10 mm)

- Flat tube width: arbitrary

- Flat tube thickness: 2-3mm

- Flat tube spacing: arbitrary

- Main slice width: any

- Name: Radiator core assembly machine and intercooler core builder

Core assembly machine Application scenarios

The application scenarios of this machine are in the automotive and industrial fields. Its application scenarios are single, but it can meet the production of various types and different sizes of products.

For example, car radiator, car condenser, car intercooler, generator radiator, computer cooling radiator, car air conditioner heater, heat exchanger and other products.

The machine is designed with reasonable working dimensions, which can meet the maximum size of 800 * 800mm and the minimum size of 260 * 300mm. It can realize the free replacement of 1 row and 2 rows of flat tubes.

If your factory produces engineering vehicles and radiators, we can design larger machines for you to meet your production needs.

Q & A

A: Our assembly machine can produce radiator, condenser, and intercooler

A: Our machines are mainly driven by servo motors

A: It is a customized machine. The maximum assembly size we make is L1800 * W1200 * T56mm, We can customize the machine according to your size

wechat

wechat