Machine Overview

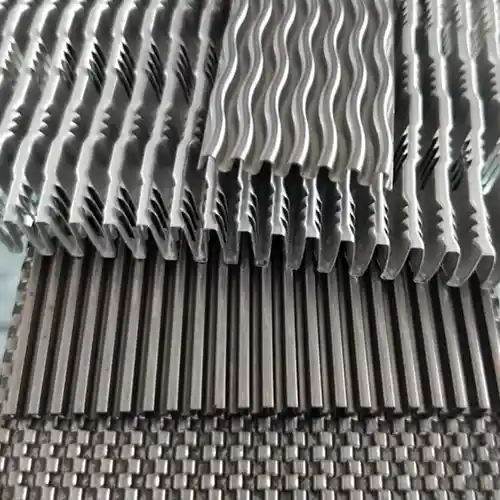

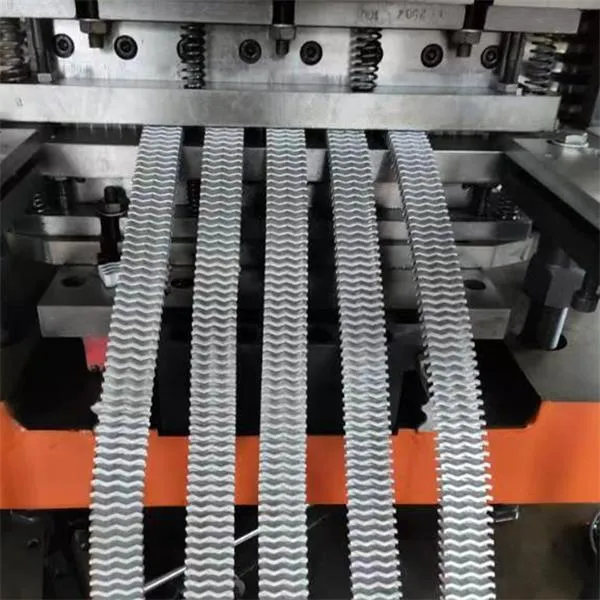

This corrugated fin forming machine is a key equipment for producing plate and fin heat exchangers. It is driven by a 7.5kw motor to rotate the main shaft and uses the cam to convert kinetic energy to achieve pressing motion

The movable board of this machine adopts a four-axis design, which runs smoothly and provides effective precision guarantee for the production of high-precision wave fins

This fin machine can press 144 times continuously at high speed per minute, which can save a lot of time and cost for factories during high-speed production

Servo control cut-off device, which can accurately control the length of fins and allow users to set fin length and production quantity

Corrugated fin forming machine technical data

| ITEM | DATA |

| Foil material | aluminum copper SS304 SS201 titanium alloy iron |

| Foil material thickness | 0.06-0.4mm |

| Fin height | 2.5-12mm |

| Fin pitch | 1mm-10mm |

| Fin Max length | any size |

| Fin max wide | 300mm 450mm 600mm optional |

| Fin type | corrugated sawtooth straight line swelling optional |

Advantages of corrugated fin forming machine

1, High power drive:

equipped with a 7.5 kW motor, which can provide sufficient power to ensure stable production

2, Four-axis design:

The activity board adopts a four-axis design and is equipped with springs and automatic lubrication devices, making the machine run more smoothly and conducive to producing high-precision fins.

3, High speed production:

The corrugated fin forming machine can continuously press 144 times per minute, which allows the factory to complete a large number of production tasks in a short time and save time and cost.

4, Servo control cut-off device:

It can accurately control the length of fins and allow users to set the length and production quantity of fins according to their needs, improving the flexibility and accuracy of production.

5, High degree of automation:

The entire production process is highly automated and can achieve unmanned production status

6, Easy to operate and maintain:

The user-friendly interface and reasonable design enable operators to quickly grasp operating methods, while also facilitating daily maintenance and upkeep.

wechat

wechat