Machine Overview

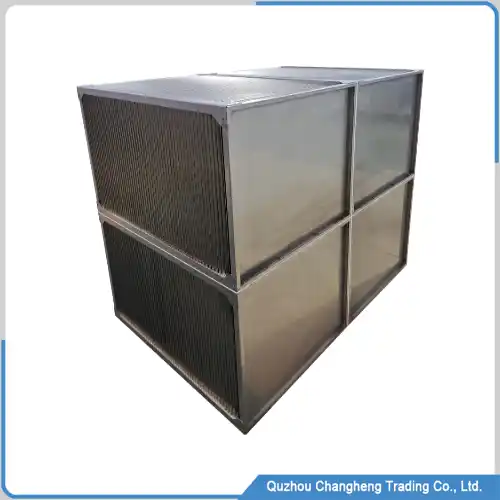

The Counterflow heat exchanger making machine is a continuous production equipment, which consists of an aluminum foil uncoiling machine, hydraulically driven pressing machine, replaceable mold, automatic transmission device, cutting device, and other parts,

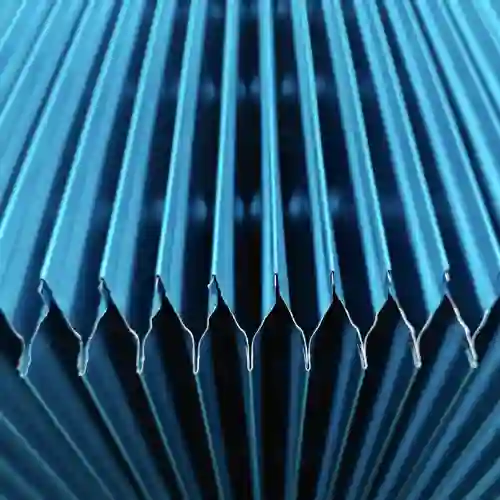

The pressing mold of this device has a good design, and one mold can produce aluminum plates for heat exchangers of various sizes, such as 500*500mm and 1000*1000mm, etc. This design can save a lot of mold costs for the factory,

At the same time, the mold can adjust the height of the aluminum plate protrusion, and this flexible design can easily change the heat exchange efficiency of the heat exchanger, meeting the requirements of different customers for the spacing between the heat exchanger plates

Please check the following video for more details on the machine

Counterflow Heat Exchanger making machine data

| ITEM | DATA |

| Power supply | 380v/50Hz |

| Control system: | PLC & touchscreen |

| Voltage: | 8kw |

| Working size | 1200-100mm |

| plate material: | aluminum foil |

| Max Production speed: | 10-12 pcs/min |

| Production type | continuous |

| Aluminum plate shape: | customized |

Counterflow Heat Exchanger machine advantage

1, The main pressing equipment adopts four-column hydraulic pressure, which can set the most reasonable working stroke to achieve rapid production

2, The transmission device is driven by a servo motor, which can accurately control the movement of the aluminum plate, ensuring consistency in height for each aluminum plate

3, The mold adopts a multi-size common design, which means that the factory only needs to purchase a pressing mold to produce multiple sizes, which is very beneficial for later investment

4, This Counterflow Heat Exchanger making machine is highly automated and does not require workers to supervise equipment during the production process, which is very friendly for saving labor costs

5, Mold pressing and servo drive transmission achieve high-speed production, capable of producing 10-12 pieces per minute, which is currently the fastest production speed in this industry

6, Compared to the equipment in European factories, our equipment has a very high cost-performance ratio, which saves a lot of investment for your new factory

The application of this machine

1

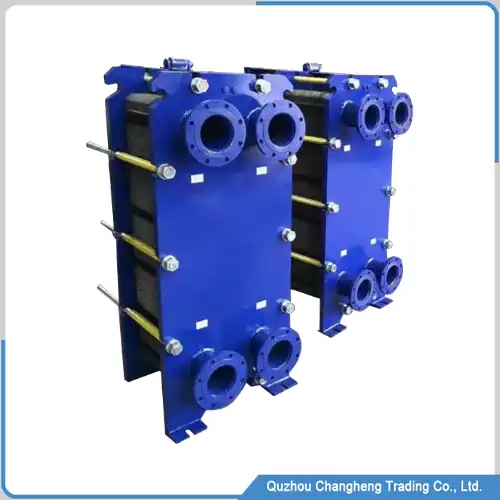

this production line can produce air-to-air heat exchangers, cross-flow heat exchangers, convection heat exchangers, etc

2

The molds of this production line can be designed with any pattern And height to meet the needs of different customers

3

Whether you are producing industrial heat exchangers or household use, this production line can meet your production needs

Q & A

A: The fastest delivery time is 65 days.

A: Our mold design is very reasonable, just change the mold settings to produce different sizes.

A: The mold has a quick replacement positioning device, and replacing raw materials takes approximately 20-30 minutes.

wechat

wechat