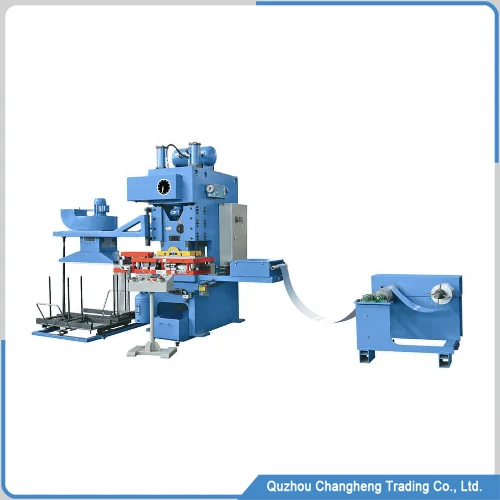

Machine Overview

The crossflow heat exchanger machine is an automated production equipment designed for high efficiency and versatility. The production line comprises a material feeding system, mold-pressing equipment, automatic conveyance devices, cutting units, and a control system. These integrated systems can automatically complete the production process, from raw materials to finished products.

The pressing mold of this production line is suitable for multiple sizes, such as 800 * 800mm and 600 * 600mm. This compatible design will significantly reduce production costs for users,

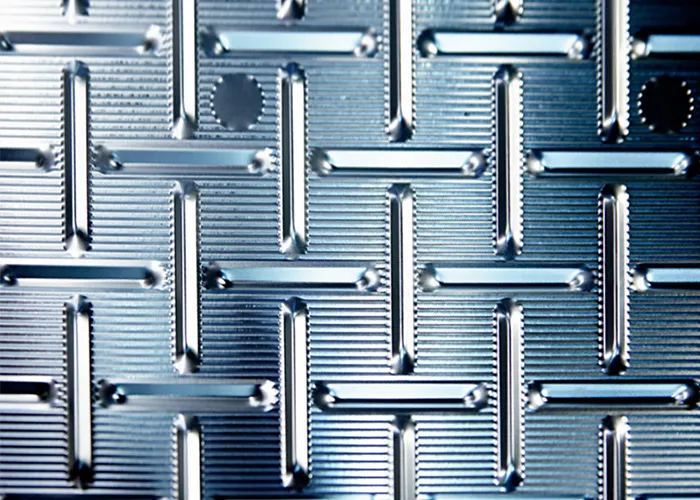

The mold’s convex hull size can be adjusted without loss, which means that the size of the heat exchanger’s air channel can be changed to meet diversified technical requirements for different customers without increasing manufacturing costs.

In addition, the control system of the cross-flow heat exchanger adopts advanced technology, with multiple production modes and product sizes built-in. If different products need to be replaced during production, there is no complex mold-changing process. Engineers can quickly complete the switching work by selecting the preset product through the touchscreen

The control system also has options for production data management, production plan control, etc., helping users optimize production processes and improve management efficiency.

Overall, the cross-flow heat exchanger machine’s fully automated production line is compact, space-saving, functionally comprehensive, and suitable for the production demands of modern factories.

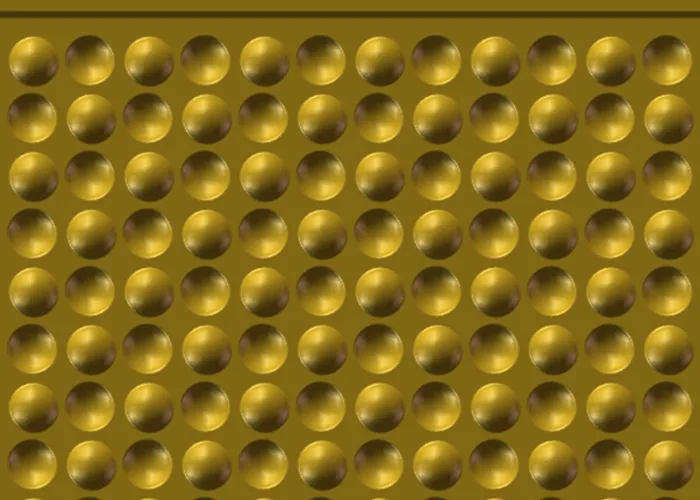

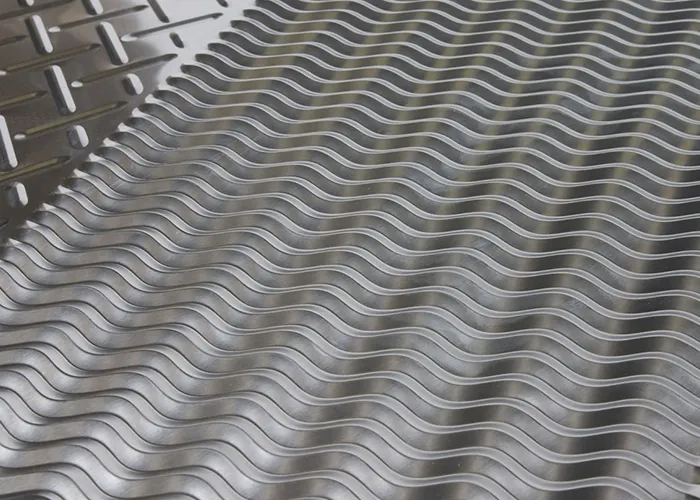

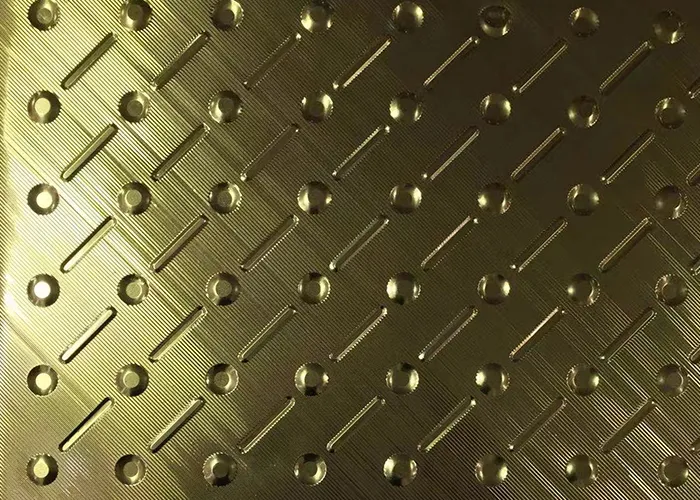

Design type of aluminum plate

We offer customized designs for Crossflow heat exchanger aluminum plates with various patterns. Regardless of how unique or complex your needs may be, our experienced mold designers are committed to ensuring that your expectations are met to perfection.

Crossflow heat exchanger Machine advantage

Automated production

Automated sheet metal production, using mechanical and servo motors to manufacture sheets accurately and efficiently.

Efficient control

This machine’s touchscreen is preset in various sizes, making it very convenient to switch between them.

Multi size sharing

Scientific mold design ensures the production of various plate sizes, meeting the diverse needs of each customer without the need for large-scale investment.

Flexible stacking tools

This tool can be applied to every size, and the edge of the heat exchanger has been bent twice, forming a good sealing effect and perfectly solving the problem of leakage

Crossflow heat exchanger Machine data

Q & A

A: It is driven by hydraulic pressure, and the motor’s voltage is 5.5kw.

A: We have automatic machines to choose from.

A: Its maximum load capacity is 12 tons, sufficient to accommodate the maximum size of aluminum foil material.

A: We provide the most easily worn parts and wrap them in disposable packaging, which helps with long-term storage.

wechat

wechat