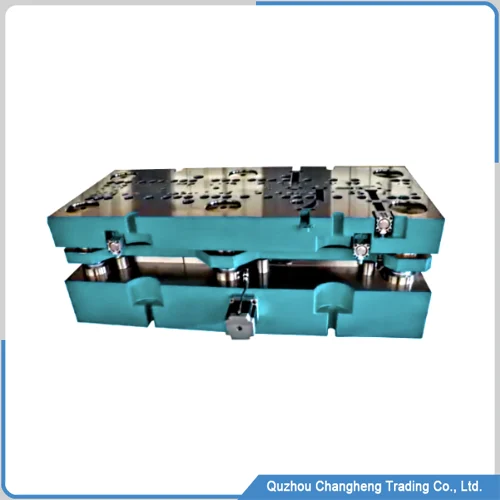

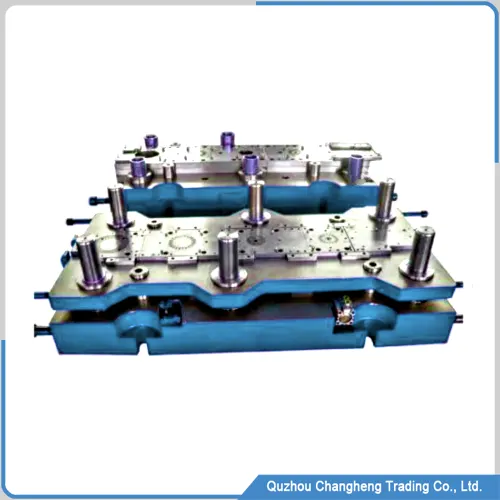

Mold Overview

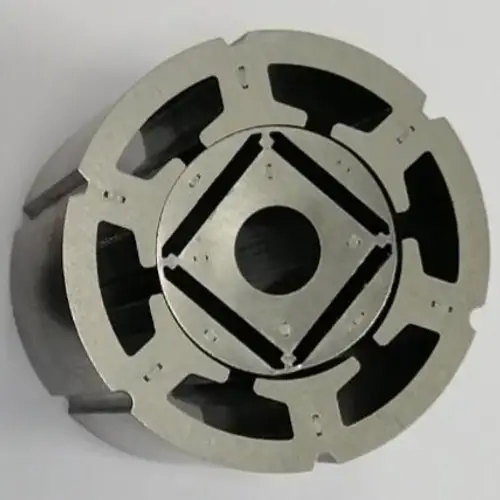

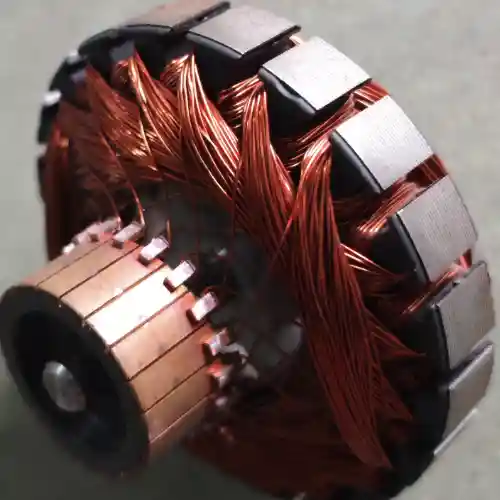

The electric motor stamping die is crucial in the electric motor manufacturing industry. It is a high-speed stamping die manufactured by precision engineering technology and is very suitable for producing rotors and stators of various electric motors.

Our mold development team has rich experience, with professional engineers completing various tasks, including stamping mold design, mold parts processing and production, stamping mold assembly, and debugging.

The important parts of motor molds are made of high-strength steel materials and have undergone high-temperature quenching treatment. During high-speed production, they will not deform and maintain good quality output. This design of the part is independent, and if it wears out over long-term use, it can be We can replace it very cheaply at cheap. The service life of the raw material stamping mold

If your motor rotor has a unique shape, we can customize this unique mold for you to meet your personalized needs,

The advantages of electric motor stamping die

- High production efficiency

This stamping mold is an automated production process that produces many identical parts at high speed in a short time. This production mode is extremely efficient and does not require labor costs.

- Consistency of parts

The mold cavity of the stamping die is scientifically designed, and the size and shape of each part meet strict tolerance requirements. The dimensions of the produced rotor and stator meet quality requirements and have good consistency,

- Easy to maintain

The important part of the motor stamping mold is independently designed. Engineers can easily replace this part, maintaining high-precision mold production and extending its service life if this part wears out.

- Quality control

Our molds and parts are precision-machined using CNC machinery to the highest quality standards. The accuracy and durability of each part meet the industry’s highest standards.

Electric motor stamping die data

| No. | ITEM | DATA |

| 1 | Parts | rotor & stator |

| 2 | Working mode | lamination |

| 3 | Production type | continuous |

| 4 | Part material | Iron |

| 5 | Shape | Circular |

| 6 | Mold material | SKH51 Cr12MoV |

| 7 | Appearance | Orange |

| 8 | Workstation | 1-6 optional |

Electric motor stamping die raw material

This high-speed production mold consists of many parts, each with some differences in metal materials. Each metal is applied in the most suitable position to extend the service life and cost control of stamping molds and maintain good competitiveness.

The key and most crucial component of the mold is usually SKH51, which has excellent wear resistance and fatigue resistance,

Ordinary and essential parts from Cr12MoV, which has undergone high-temperature quenching treatment. It is incredibly fatigue-resistant, not easy to crack, and stable.

Ordinary parts come from CN45 steel, which not only has a good cost-performance ratio but also has very good toughness, making it very suitable for manufacturing templates and frame parts

Why choose our mold

1. Rich work experience: Engineers in this field have over 15 years of work experience.

2. Independently designed vulnerable parts allow for quick and low-cost replacement of worn parts.

3. Install servo motors in special molds. The special rotor-stator must rotate out. We have configured a servo motor for the mold to control the rotation angle accurately.

4. We manufacture our stamping molds with high-precision equipment To ensure that the mold can produce rotors at high speed for a long time.

Electric motor stamping die working video

Q & A

A: It can produce laminated rotor and stator types.

A: Usually, Our delivery time is 45-55 days.

A: Of course, You can choose any color.

wechat

wechat