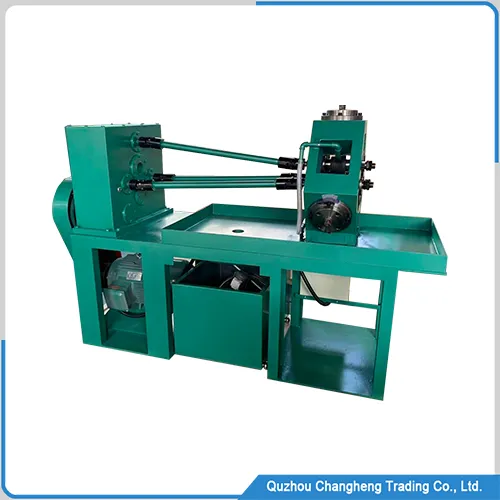

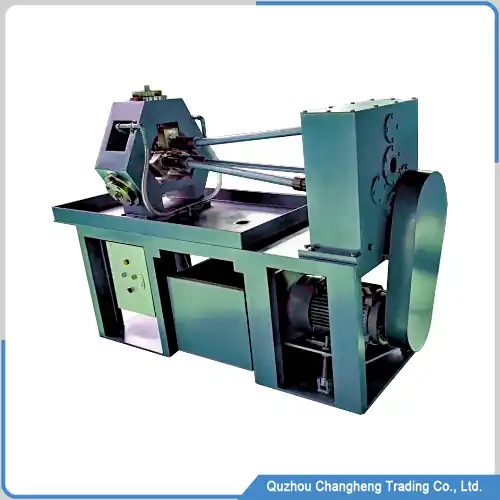

Machine outline

This type of extruded fin tube machine involves nesting two types of metal tubes together through extrusion. The inner tube can be made of any metal material, while the outer tube is typically made of aluminum or copper.

This machine is driven by an 11kw motor, and outputs three groups of power through gear speed change. Each group of power has a ball joint connected to the roller mold. The three groups of roller mold have strong power, so it can efficiently produce fin tube

The tube fin is produced by extrusion, and the fin base is closely attached to the outer wall of the tube, with almost no gap. Therefore, this fin tube has the most thermal conductivity at present.

Extruded fin tube machine data

| No. | ITEM | DATA |

| 1 | Outer Fin height | <17mm |

| 2 | Outer Fin material thickness | 0.2-0.6mm |

| 3 | Outer Fin material | Aluminum, Copper optional |

| 4 | Base tube diameter | 10-38mm, 8-51mm |

| 5 | Fin tube outer diameter | Φ25-88mm |

| 6 | Fin pitch | 0.6-2mm 1.6-5mm |

| 7 | Max length | <20m |

| 8 | MOQ | 1 pcs |

| 9 | Delivery time | 65 days |

| 10 | Base tube material | Aluminum, SS304 copper, alloy |

Other types of fin tube machines

Low fin tube machine supplier

Machine Overview The low-fin tube machine is the equipment used in the heat exchanger industry. It is driven by an electric motor, which rotates the spindle and rolls the mold to extrude metal tubes into…

Spiral tube machine

Machine Overview The spiral tube machine is mainly driven by an 11kva motor, which provides strong power to rotate three sets of roller molds and extrude metal tubes into a spiral shape. This tube type…

Fin winding machine for Spiral fin tube

Machine outline This equipment uses a 2.5kw motor as the primary power source, and its structural design is effortless, making future maintenance and repair work very easy. Workers do not need to undergo strict training…

Advantages of Fin Tube Machine

- Adopting a three-axis roller design

Each group of roller mold has power, flat and uniform speed. The fin tube is evenly during extrusion, so it can stably output tube with the same fin pitch This design not only improves production efficiency, but also ensures stable quality output

- Automatic circulation of coolant

The extruded fin tube machine is equipped with an automatic circulation cooling system. After the coolant is circulated, it will pass through a filter screen to isolate debris and impurities, ensuring the cleanliness of the coolant. In addition, this coolant can effectively prevent the roller mold from overheating, ensure stable production of the machine, and extend its service life.

- Simple control system

The control system design of this machine is very simple, and workers can operate it directly without receiving training on the testing machine, reducing the threshold for using the equipment It also saved a lot of training time

- There is no limit on the length of tube

The machine adopts a hollow design. In theory, the left and right shelves of the machine can have unlimited length. But in order to transport tube smoothly, it usually produces 6 meters of fin tubes. If your requirement is 15-2 meters, the extruded fin tube machine can also meet your requirements

- Flexible mold changing structure

The roll mold adopts replaceable design, and the cost of the mold is very cost-effective. This is a genius design. Users only need to spend very low costs to produce tube with different fin pitches, which can not only meet the requirements of different customers, but also reduce a lot of production costs.

Extruded fin tube machine working video

Q & A

A: Usually, the appearance of this machine is green, but I can accept spraying other colors.

A: If you purchase our machine, we provide free installation services, but you need to pay for the engineer’s air tickets, hotel, and food.

A: The delivery time for this machine is 41 days.

A: Changing the mold of this machine is very easy, and it only takes 30 minutes for a new engineer to replace the mold.

wechat

wechat