Product Description

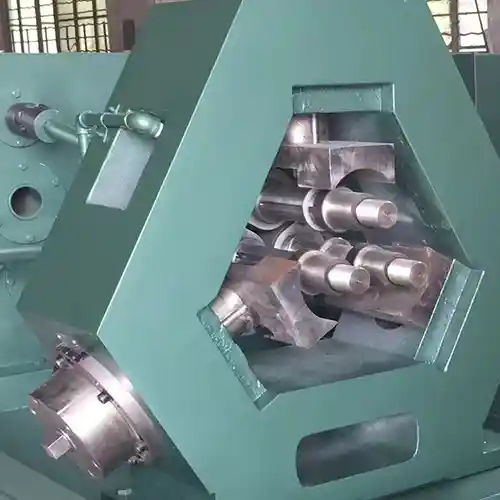

The Extrusion fin tube machine has 3 shafts to rotate the extrusion roller to produce two metal tubes. This machine can produce various types of heat exchangers

This fin tube machine is driven by an 11kw electric motor, three rollers, an Automatic circulation and filtering cooling liquid system, and a control system

We can customize the working size of this machine according to the customer’s fin tube design,

Our latest generation of machines has changed the structure design and arrangement of the universal joint.

The machine is very quiet when producing fin tubes. The coolant will not overflow. It can produce fin tubes of any length and size

Extrusion fin tube machine Technical Data

| Name | Data |

| Finned tube OD | ɸ25 – 77mm |

| Base tube diameter | ɸ15 – ɸ45mm |

| Fin thickness | 0.15 – 0.45mm |

| Fin materials | Alu / Copper |

| Fin height size | 7-16mm |

| Base tube materials | Aluminum SS304 copper |

| Spiral pitch | 1.5-8mm customized |

| Machine weight | 1.95T |

| Overall dimension | 2*0.8*1.5m |

| Motor power | 11kw |

| Power Supply | 380v / 50Hz |

Extrusion fin tube machine Features

1. The three sets of roller molds are arranged in a triangular layout, which is the most stable design, ensuring the quality of the fin tube is consistent.

2. This machine has a cooling fluid circulation device, which can quickly cool the mold blade and extend its lifespan.

3. The machine will not have any media overflow during the production process, and it will not cause any pollution to the environment. It meets the strictest environmental protection requirements of each country.

4. The two sides of the machine are designed to be hollow. It produces fin tubes, which are not limited in length. Theoretically, it can produce fin tubes of any length.

Extrusion fin tube machine working video

Q & A

A: Contact our engineer, and we will send the catalog and video

A: We bought ship transportation insurance for the machine

A: Our machines are pack in wooden cases

A: The delivery time is 45 days

A: The raw material of the outer tube of our machine can be aluminum or copper

A: Our machine weighs about 1.95 tons

wechat

wechat