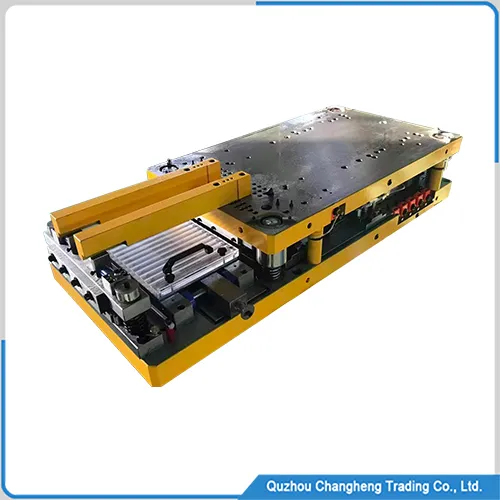

fin cutting machine outline

The servo motor-driven fin cutting machine has very high accuracy and stability. It uses a servo motor as the driving source, enabling precise motion control,

and ensuring consistency and stability in cutting length. At the same time, the efficiency and stability of servo motors are also very suitable for cutting work that requires high accuracy and speed.

It cooperates with our fin-making machine to achieve unattended, fully automated production

| ITEM | DATA |

| machine name | cutting machine |

| Drive motor | servo motor |

| Touch screen | 7 inches |

| Power supply | 220v |

| Custom Parameters | Yes |

| Replaceable | Yes |

| machine Colors | customizing |

fin cutting machine superiority

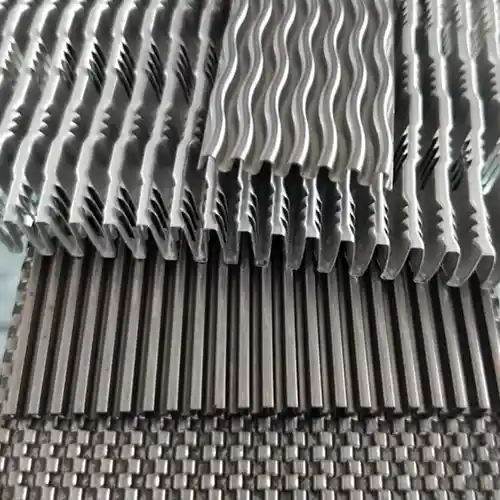

In addition to high accuracy and stability, servo motor-driven fin-cut off machines is also suitable for a variety of materials.

Whether it’s copper, aluminum, stainless steel, iron, or titanium alloy, it can handle it easily.

The cutting blade adopts a double cylinder structure design and can be adjusted according to different materials, Make it applicable to various materials.

Simply replacing the rollers can easily produce different types of fins, such as serrated, wavy, and linear, which can save a lot of money for your factory

This machine is already equipped with a touch screen, allowing users to customize preset parameters based on different fin sizes

summary

In practical applications, servo motor-driven fin-cutting machines can not only improve production efficiency but also improve product quality.

It can achieve efficient cutting work, and ensure good consistency in product quality and length, thereby improving the production efficiency and competitiveness of enterprises.

If you are looking for an efficient, accurate, and stable fin cutter, a servo motor-driven fin-cut-off is your best choice.

wechat

wechat