Machine Overview

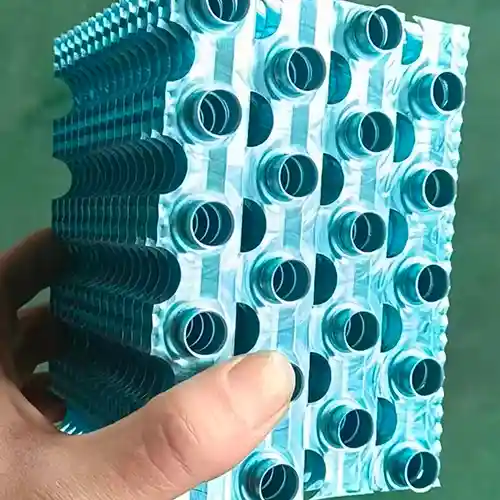

The fin press machine is an efficient production equipment mainly uses for the automated manufacturing of parts for heat exchangers, air conditioners, and refrigerators. With an astonishing speed of 280 presses per minute, many factories choose this press machine as their primary production equipment.

The machine’s technical parameters, such as slider distance, pressing pointer, pressure, etc., are displayed on a digital screen. The main screen also displays device production data. When the machine has a fault, the screen also displays a fault code. Engineers can quickly turn off the fault and let it run normally.

This fin press machine is a complete production line and runs excellently. With this device, you don’t need to make any modifications or upgrades. It only needs to be connected to a power source and compressed air to function properly.

Technical data

| ITEM | DATA |

| Capacity | 450 KN |

| Slide of Stroke | 40MM |

| Die Height | 200~270mm |

| Overall Dimensions | 650×250×233cm |

| Main Motor Power | 5.5kw |

| Size of Table(H×W×T) | 80×58×10cm |

| Sucking Length | 100cm |

| Stroke | 150~250 S. P. M |

Fin die data

- φ9.52-25*21.65 12 rows 1P

- Φ9.52-25*21.65 12rows 2P

- Φ12.7-31.75X*27.5 12Rows 1P

- φ9.52-25.4*22 12rows 1P

- φ15.88-38.1*33 6rows 1P

- φ3/8-30*30 6rows 1P

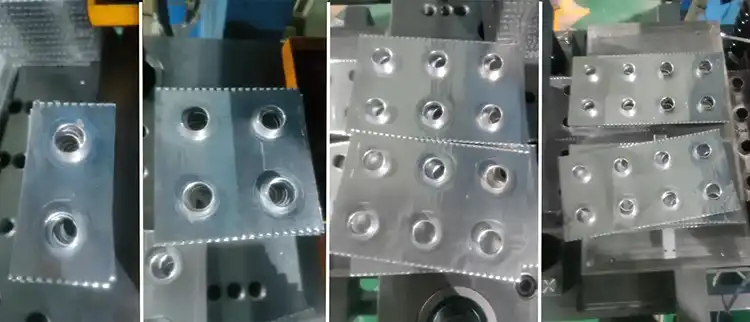

Fin press machine features

High-precision electric debugging

The key component of the fin stamping machine, the slider, is electrically adjustable with a maximum accuracy of 0.01mm. Whether the slider moves upwards or downwards, it can be easily adjust by simply pressing the button,

Multi-language support for touch screens

Multi-language support is the best for users because many functions and data show on the touchscreen display. No matter which country you come from, you can find the language you need

Super strong mold compatibility

This fin press machine’s worktable size is 800 * 580mm, which can accommodate almost 90% of the molds on the market. Whether your fin mold is wave, straight, louver, or any other type, this equipment can perfectly produce it.

Intelligent security control

Each key part of the fin punching machine is equipped with safety sensors, and any illegal operation will not be carried out. It will automatically issue warnings and screen prompts for error correction, ensuring absolute safety during the production process.

Fin press machine working video

Fin press machine advanced function

- Endless changes in production speed

The machine is driven by an asynchronous motor, which is effectively connected to the gearbox to increase power output. Engineers can change the motor speed value through the touch screen to control the production speed of the machine,

This infinite shifting method, without any shifting action, can effectively ensure smooth power output and provide good quality assurance for the production of heat exchanger fin parts.

- There are multiple pneumatic controls

The fin press machine retains multiple external pneumatic control interfaces, and users can connect these interfaces according to different application needs to control these external devices and achieve intelligent production centrally.

If users do not need to connect any tools, these interfaces will not occupy any space and will not consume electricity. They are reserved for more automated production.

Other heat exchanger machines

Water Pressure Tube Expanding Machine

Product Description This water pressure tube expanding machine consists of a control system, a boosting device, and an expansion joint. It injects tap water into the inside of the pipe and increases the pressure to…

Vertical expander machine of Heat exchangers

Product Description This vertical expander machine is key equipment for producing household air conditioning condensers. It expands the diameter of copper pipes vertically, allowing the cooling fins and copper pipes to be tightly combined. Usually,…

Tube straightening machine

Machine Overview The tube straightening machine is an automated equipment in the heat exchanger industry. It integrates the functions of feeding, straightening, cutting, and storing metal tubes. It has six independent workstations, each of which…

Fin press machine application field

Car radiator: It is an important cooling component for internal combustion engines,

Car air conditioning heater: This machine produces heaters; almost all heaters require this equipment to make their fin parts.

Bus: Some city buses require this machine to produce external air conditioning condensers

Home air conditioning: This is the most widely used field, with 100% of factories using this machine to produce home air conditioning condensers

Home heater: In cold northern cities, indoor heating is needed to maintain a comfortable temperature in winter, and the heater is a component produced by the fin press machine

Household appliances: Some special household motor parts require the production of this equipment

Heat exchanger: In the industrial field, large-scale heat exchangers require this machine to produce fin parts, and there is currently no better alternative equipment available

Condenser: Industrial condensers are generally large, and their fins need to be produc vertically, which happens to be the strength of stamping machines.

Q & A

A: Of course, it can produce aluminum and copper materials, stainless steel, and titanium metals.

A: This machine has three oil tanks for adding lubricating oil, and you only need to press the handle of the oil tank once a day.

A: Yes, it has this

wechat

wechat