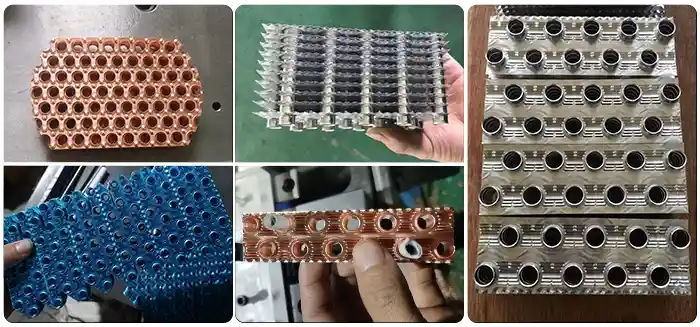

Mold Overview

1. This fin Progressive die is suitable for automobile radiators, household air conditioners, central air conditioners, dehumidifiers, etc.

2. It is suitable for aluminum foil with different states and thicknesses at home and abroad.

3. All steels are made in Japan or Sweden, and the cutting edge material is asp30 or hap40.

4. The mold is easy to maintain and use, and the interchangeability of parts is excellent. All standard parts (including guide post, guide sleeve, spring, screw, etc.) are Japanese Misumi products.

Technical parameters of Fin Progressive die

- Model: Φ 8.35 × 12R

- Number of columns: 12R

- Inter-column cut-off: Quickly cutting each column

- Fin material: aluminum foil t = 0.12-0.15mm

- Flanging height: 1.8mm (0-0.1mm)

- Quantity: 1 set

- Stamping speed: 120-250 times/

The single die repair can guarantee 20 million punching times, the knife edge can be repair 10 times, and the mold’s total service life is 15 years.

Punching and flanging → straightening, edge cutting → longitudinal cutting → feeding → cross-cutting

Air conditioning fin mold, high flanging fin mold, automotive air conditioning fin mold, industrial heat exchanger fin mold, refrigerator fin mold, unique purpose heat exchanger aluminum fin die,

This fin Progressive die suits household air conditioners, central air conditioners, automobile air conditioners, industrial heat exchangers, dehumidifiers, industrial radiators, etc.

It is suitable for aluminum foil of different states and thicknesses and can be customized. The specifications for copper tubes are 5-15.88mm, etc.

All steel materials are imported from Japan or Sweden, and the cutting edge material is made of powder high-speed steel ASP3.0.

The mold is easy to maintain and use, and the interchangeability of parts is excellent. All parts such as guide post, guide sleeve, spring, and screw, are important products.

Fin Progressive die Manufacturer’s factory video

Our service

Fin progressive die Design

We accept customers’ size requirements for heat exchangers and manufacture these molds. Whether you need this mold to produce any metal materials, we can provide a good solution to help you solve the problems in the production process and achieve full auto production.

Maintenance

We also provide mold maintenance services. As everyone knows, the design of this structure’s fin progressive die is very complex, and each part must meet strict size requirements. Ordinary mold factories find it challenging to maintain this mold, so we offer this professional maintenance service to extend its lifespan.

Training

We will provide training services if you are a new factory and purchase our progressive dies. Usually, these services are free, and you only need to cover the expenses for our engineers’ airfare, hotel, visa, food, etc.

Sea transport

You don’t need to get involved. We will send the molds to your factory, but of course, your company must have the right to import them.

wechat

wechat