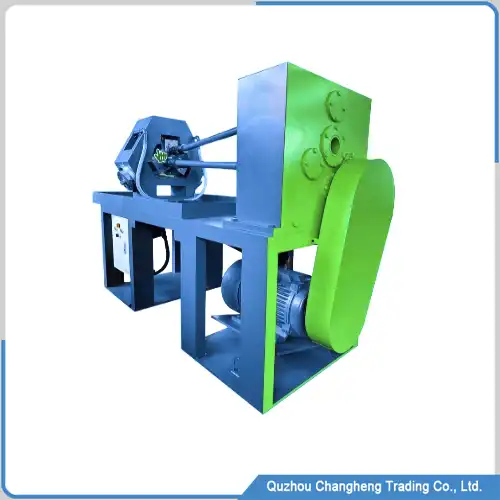

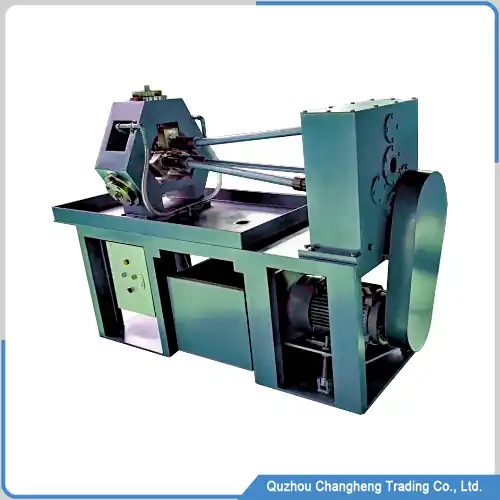

Machine Overview

This finned tube machine can produce low-finned tubes, 2-metal tubes, and single-metal tubes. These tubes are mainly used in industrial cooling, the petroleum industry, ships, etc.

The main driving force of this device comes from an 11kw motor, which drives the gears to output strong power at a variable speed.

The roller mold of this machine is through a universal joint connection, and users can easily adjust the spacing between three sets of rollers to produce fin tubes of different diameters,

The adjustment screw has a scale display, and engineers can quickly and easily adjust it according to the diameter of the fin tube.

Finned tube Machine list

Tube Finning Machine Manufacturer From China

Machine Outline This tube finning machine is suitable for producing two different metal finned tubes. It produces pipes with different pitches by replacing the blades…

Spiral tube machine

Machine Overview The spiral tube machine is mainly driven by an 11kva motor, which provides strong power to rotate three sets of roller molds and…

Low fin tube machine supplier

Machine Overview The low-fin tube machine is the equipment used in the heat exchanger industry. It is driven by an electric motor, which rotates the…

Finning tube machine of Heat exchanger

Product Description The extrusion aluminum finning tube machine adopts the form of an aluminum tube as the base tube, and after being extruded by the…

Fin winding machine for Spiral fin tube

machine outline This equipment uses a 2.5kw motor as the primary power source, and its structural design is effortless, making future maintenance and repair work…

Fin tube rolling machine at best price in china

Machine Outline This fin tube rolling machine specializes in producing two metal spiral fin tubes with different diameters. It can produce special finned tubes for…

Finned tube Machine working video

Technical parameters of the machine

Features of machine

1. Highly competitive prices

The finned tube machine has been scientifically designed, and its structure is sturdy. It is compact in appearance, does not take up too much factory space, and has a high cost-performance ratio. It is one of the best equipment for producing extruded fin tubes

2. Humanized control device

The machine has been simplified in design, and its control device does not have complex processes. Workers only need simple training to use this tube wing machine easily,

3. Molds for multi-scale applications

Adjusting the gap of the roller mold, producing fin pipes of different diameters, And the design of this finned tube machine mold can significantly save the operating costs of the factory

4. Automatic lubrication system

The pressure roller squeezes the finned tube and generates a large amount of heat, requiring timely cooling of the roller mold. Therefore, the machine has a coolant tank with a water pump to circulate the coolant.

Finned tube Machine advanced function

1. This machine’s motor and gearbox use a unique Power Transmission Belt; these belts have a certain degree of elasticity and can generally be used every season without any power attenuation.

In special circumstances, the electric motor’s rotating disc can be replaced with a larger-diameter rotating disc to produce faster production speed. This situation is usually applied to aluminum low-fin tubes.

2. Roller molds are design with flexible replacement. Different types of molds can produce various kinds of pipes, such as spiral pipes, low-fin pipes, threaded pipes, etc. These pipes are widely use in the heat exchanger industry

Why choose our finned tube machine

We are one of the best machine suppliers in China, and we have many years of deep cultivation in this field. We can provide the best equipment prices and satisfactory after-sales service. No matter your machine’s problems, we will answer your questions immediately.

We have a complete set of instructions for designing this fin tube. This manual can help you solve 80% of the problems.

wechat

wechat