Machine Overview

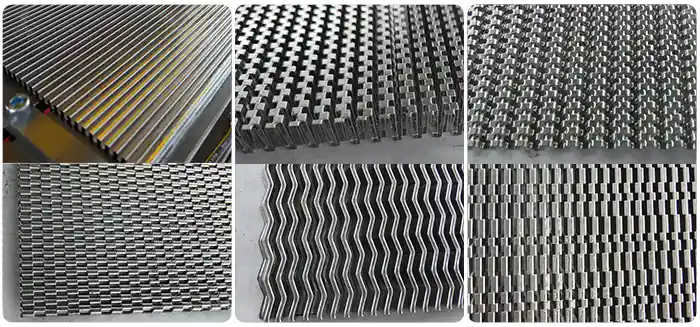

We are an aluminum fin machine manufacturer from China. This machine is one of the important equipment for producing plate and bar-type heat exchangers. It features a flexible design with replaceable molds, allowing users to produce various shapes of fins at low cost.

Our fin machine is Driver by a 7.5kw motor, which outputs strong power through gear changes to meet the production needs of different metal fins, such as aluminum, copper, iron, stainless steel, etc.

Finning machine manufacturer advantage

1, Price advantage.

When you buy an aluminum fin machine from us, no middleman makes a profit, and you only need one machine. We’ll also give you the best wholesale price.

2, Professional service.

No matter how complex your fin shape, our engineers can design the most suitable fin mold to meet your requirements.

3, Fast delivery.

Since the aluminum fin machine manufacturer specializes in producing this machine, there is usually stock in the warehouse, and we can provide fast delivery.

4, Extremely long warranty period.

This “fin” machine has undergone rigorous market validation and can have a long lifespan, even without maintenance. Therefore, we are confident we can offer an ultra-long warranty period.

Aluminum finning machine production process

- Place a roll of raw metal material on the feeder and install it securely. The machine automatically feeds the material when the distance sensor switch contacts the aluminum foil. When another sensor switch contacts the aluminum foil, the machine will stop feeding the material.

- Metal materials will be lubricated through an oil tank, and then the mold of the aluminum finning machine will press the material into the shape required. This process is fully automated production without any intervention from workers.

- The finish fins go through the cutting machine and are cut to the set length. This is the entire production process of the fin machine.

Aluminum finning machine working video

Advanced function of aluminum finning machine

The width of this fin machine is 300mm, and it can produce 2 fins with a width of 140mm at the same time or multiple small-sized fins. This means a geometric increase in production efficiency.

You can set the production output through the screen, and the machine will automatically count. When the production output meets the set requirements, the machine automatically stops and sends a blue alarm.

Sensors are installed in multiple machine locations. If a worker operates the machine illegally, a warning will be issued, and a fault code will be displayed on the screen.

Q & A

A: Our delivery time for this fin machine is 45-55 days.

A: Its default color is green, and the key position is orange.

A: This fin machine is a PLC control system.

A: The packaging of this machine is a wooden box.

A: The machine takes about 1-2 hours to replace the mold.

wechat

wechat