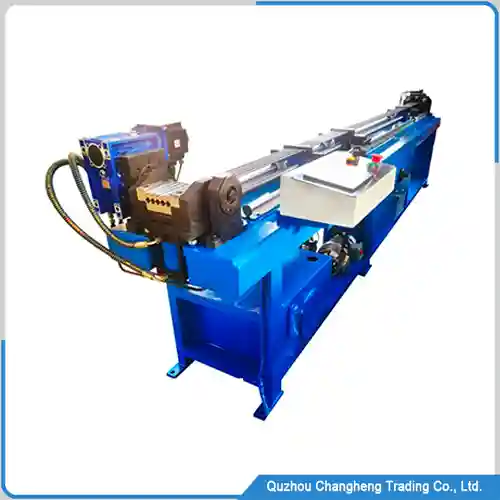

Hairpin bender machine outline

The Hairpin bender machine is a device suitable for use in heat exchanger factories, mainly used to bend copper coils into a U-shape. This type of machine is crucial for the production and quality of heat exchangers.

working principle

The working principle of the Hairpin bender machine is to manually feed the copper tube into the bending mold,

and the bending machine will bend the copper tube into the desired shape. Machines typically have multiple workstations and can bend multiple copper pipes at once.

Technical parameters

| ITEM | DATA |

| Copper pipe specification | OD5mm-OD12.7mm |

| Pipe wall thickness | 0.25-0.5mm |

| Pipe length | 200-3000mm |

| Maximum bending | 8 pieces |

| Bending central moment | 25.4mm customizable size |

| Power supply | 380V 3-phase 50Hz |

| Total power | 10kw |

| Air source pressure | 0.5~0.6Mpa |

| Hydraulic station pressure | 4-6Mpa adjustable |

Hairpin bending machine particulars

1, Hydraulic system

It is one of the key components of the Hairpin bender machine. It can provide sufficient force to bend copper pipes. Hydraulic systems typically consist of pumps, cylinders, control valves, and pressure gauges. This device is already equipped with a servo motor-driven hydraulic station, which achieves many advantages such as silent operation and power saving

2, electrical system

Electrical systems typically include components such as PLCs, controllers, sensors, and indicator lights. The function of the electrical system is to ensure the safety and reliability of the machine during operation.

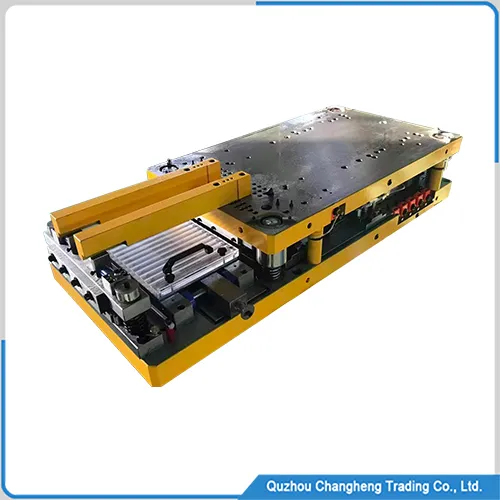

3, Mechanical structure

It is the foundation of the Hairpin bender machine. The durability, flexibility, and operability of this machine have all reached the best level in the industry,

This device has a compact design and a small footprint, making it highly favored by customers

Hairpin bender machine video

Q & A

A: We are a professional machine supplier from China, We are the most professional supplier of production machines for radiators, condensers, heat exchangers, etc

A: Traditional hydraulic stations use ordinary motors, while our hydraulic stations use servo motors, The time the machine waits, it will stop running and Will not consume electricity

A: Our ordinary machine can bend 4 pipes, which is the most common, We accept customized machines with 6/8/12 pipes

wechat

wechat