Machine outline

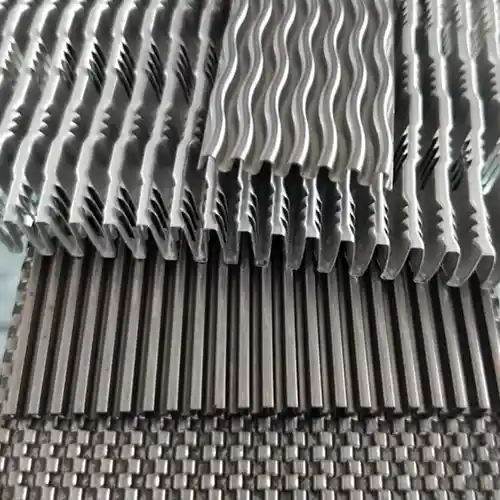

A heat exchanger fin machine is a device for producing cooling fins. It can also manufacture metal materials such as iron foil, copper foil, stainless steel foil, and titanium alloy foil.

It plays an essential role in the manufacturing of plate and bar type heat exchangers. this machine can produce fins of various shapes and achieve an unmanned production mode.

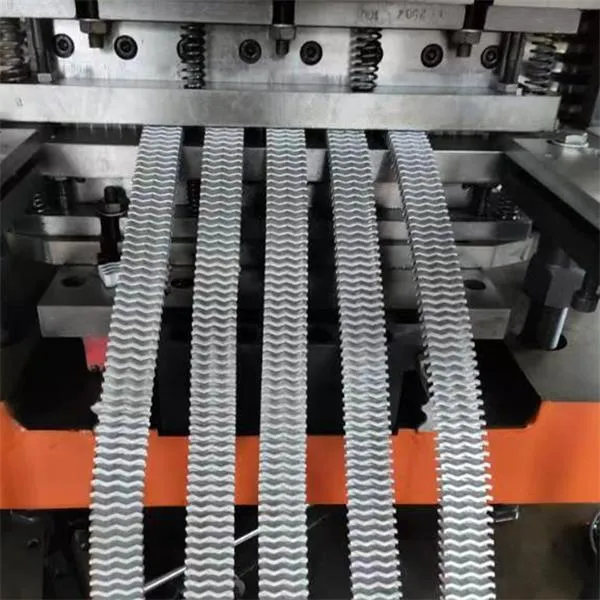

This machine consists of a continuous pressing production machine, feeding device, automatic cutting device, etc.

Technical parameter

Heat exchanger fin machine merit

1, The machine adopts a four-column design, with high-precision bushings between the pressing plate and the column to ensure smooth equipment production.

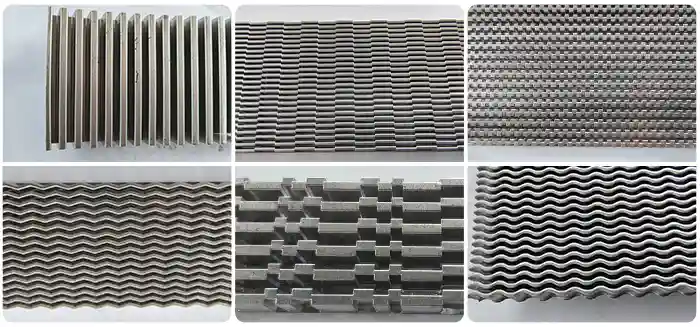

2, Independently design fin molds, so users can replace it cheaply and produce fins of different shapes to meet their diverse needs.

3, The maximum production fin width is 300mm, which means it can produce any raw material smaller than 300mm. If your fin width is 150mm, it can produce 2 fins at once

4, The unmanned production mode can save a lot of labor costs for the factory,

Heat exchanger fin machine working video

Other types of Heat exchanger fin machines

Fin punching machine of Heat exchanger and oil cooler

Machine Overview The Fin punching machine is one of the key pieces of equipment for manufacturing heat exchangers, oil coolers, and intercoolers. The fin stamping machine is mainly used for manufacturing fins in metal foil…

Fin roller machine | condenser fin machine

Machine Overview the radiator fin roller machine is the key machine for processing condensers, radiators, and intercoolers; its total power is 3.5kw. The fin roller mold is made with high precision. The servo motor counting…

Fin progressive die of heat exchanger

Mold Overview 1. This fin Progressive die is suitable for automobile radiators, household air conditioners, central air conditioners, dehumidifiers, etc. 2. It is suitable for aluminum foil with different states and thicknesses at home and…

Support and Services

- We provide users with sufficient vulnerable parts to ensure that the fin machine can be used generally in the user’s factory for 3-5 years.

- The warranty policy for this heat exchanger fin machine is 12 months. If the machine malfunctions, we provide free repair services.

- Because we specialize in plate and bar aluminum heat exchangers, we can send engineers to provide on-site training services.

- All machines and molds will be tested in factories in China. We can provide users with free fin samples.

- We can customize any type of fin mold according to the user’s fin design.

Summarize

This machine is specialized in producing aluminum heat exchangers and oil cooling equipment. Its structural design is reasonable, production is fast, and it has many advantages, such as flexible mold-changing

We are a high-quality supplier of heat exchanger fin machines from China. If you are looking for this type of fin machine, we can provide full technical support and excellent cost-effectiveness.

Thank you for reading

wechat

wechat