What does the provide

Heat exchangers are essential products in modern society. With the intensification of global climate change, people’s demand for air conditioning is constantly increasing. Many people want to buy heat exchanger manufacturing machines to build factories and earn some profits.

The production of heat exchangers requires multiple different machines, and each process requires different machines to complete different production processes.

Due to the lack of technical support in the new heat exchanger factory, users may overlook some important details when purchasing the entire production line, leading to fatal errors, economic losses, and time waste.

Our company provides one-stop solutions and technical support to help customers quickly start the normal production of heat exchangers and condensers in their new factories, avoiding unnecessary losses. Our engineers have an average of more than 15 years of work experience and the latest technology to help you achieve your goals.

If you want to start producing heat exchangers and condensers, then this article may be very helpful to you.

Heat exchanger making machine Related equipment

How to produce heat exchangers

Heat exchanger making machine List

Application of Heat exchanger

- Industrial sector

These heat exchanger making machines can produce large-scale industrial heat exchangers in industrial fields such as petroleum refining, power plants, energy and chemical industries, etc.

- Home air conditioning

The characteristic of this product is its thin cooling body and moderate volume. Its core needs to be bent to adapt to the installation of the outdoor air conditioning unit.

- Automotive industry

This type of radiator is relatively small and mainly used to cool the heat of the car engine. Another product is the condenser of a refrigerated truck, which exchanges heat for the onboard refrigeration system.

- Shipbuilding industry

In the shipbuilding industry, many heat exchangers and condensers are needs, each with different sizes, so the demand in this industry is also huge.

Heat exchanger making machine function

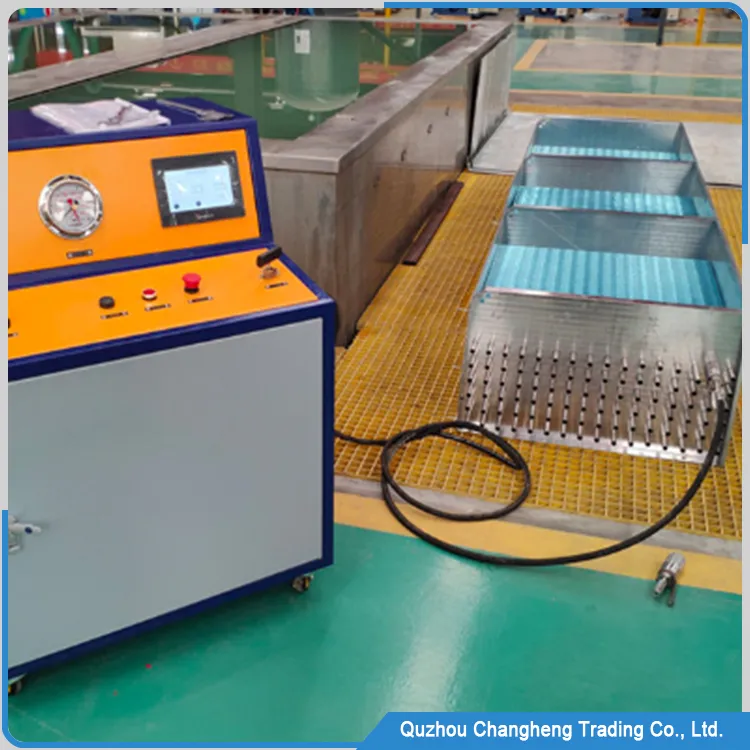

Fin making machine

This machine is to produce fins for heat exchangers, and it requires the installation of molds to function properly. The molds are designed according to the user’s size and shape, and it is one of the most important heat exchanger manufacturing machines,

The main feature of this fin production machine is high-speed continuous stamping, with a maximum speed of about 260 times per minute

Core bending machine

The function of this heat exchanger making machine is to bend the body of the condenser to the required angle. The condenser of a household air conditioner needs to be bent to save space, and this machine plays an important role.

It is a servo motor-driven device that can freely set the bending angle according to the different shapes of the condenser, which means that users only need one machine to meet all production needs.

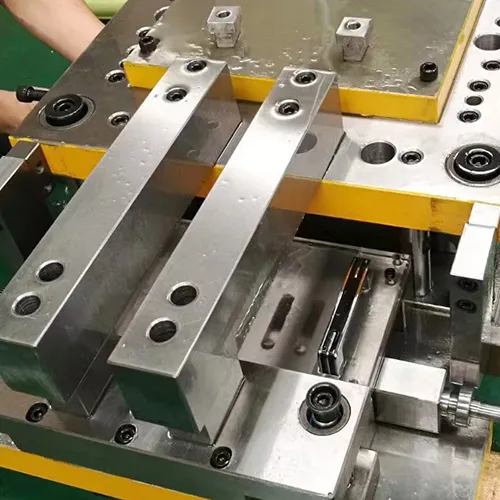

Fin stamping die

Manufacturing this stamping mold requires high-precision equipment, the mold needs to meet the requirements of high-speed production, and the parts need to consider wear resistance fully. It is one of the most important molds in heat exchanger production.

This mold has a flexible design can change the geometric layout according to user requirements to meet diverse market demands.

Hairclip tube bending machine

The function of this heat exchanger making machine is to bend copper tubes. It bends straight copper tubes into the shape of hair clips.

A servo motor drives the machine and has multiple different functional components to achieve automated production.

It can not only adjust the length of the hair clip tube to any length, but also work on multiple workstations simultaneously to provide production efficiency. Changing tools can also produce tubes of different sizes.

wechat

wechat