Machine Overview

The high-speed fin machine is a specialized equipment for producing cooling products. Here, we mainly introduce two types of machines: one for producing HVAC heat exchangers and the other for producing plate and bar heat exchangers.

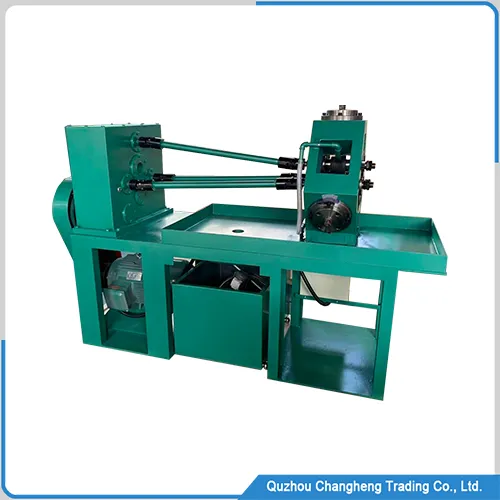

The HVAC fin press machine is a high-speed stamping machine that consists of a feeder, lubrication device, stamping machine, mold, and receiving machine. Its fastest production speed is approximately 200-260 times per minute.

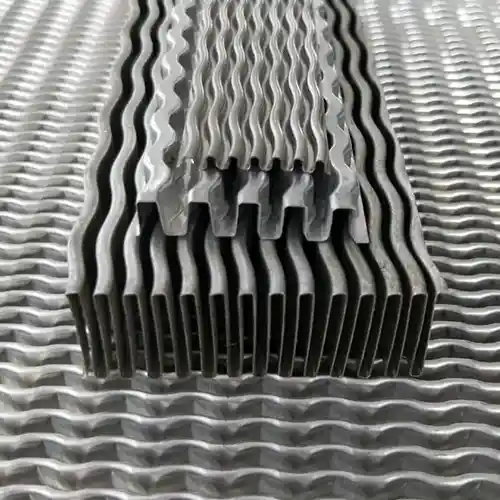

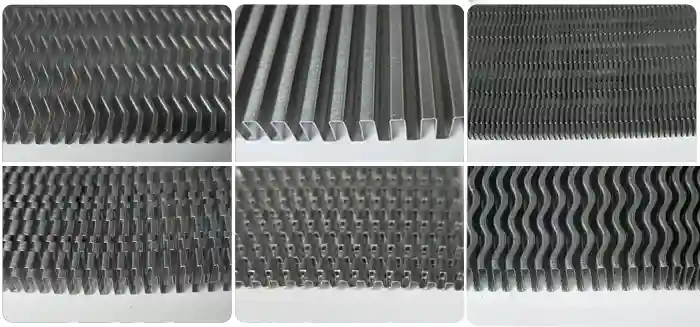

The plate and bar fin-making machine is a small device that produces fins of different shapes, such as sawtooth, wave, flat, etc. Its maximum press pressure is 5-8 tons, and its fastest production speed is 144 times per minute.

Their common feature is that the molds can be replaced, and the entire production process does not require human intervention, achieving fully automated production.

High speed fin machine Machine List

Fin stamping machine of condenser and heat exchanger

Machine Overview The high-speed fin stamping machine produces heat exchanger and condenser fin parts. It can reach a maximum speed of 280 times per minute, currently the highest level in…

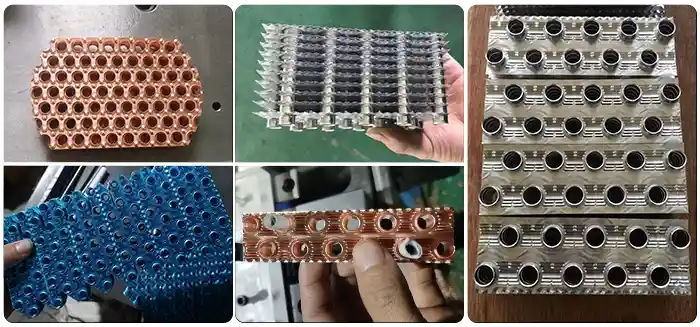

Fin punching machine of Heat exchanger and oil cooler

Machine Overview The Fin punching machine is one of the key pieces of equipment for manufacturing heat exchangers, oil coolers, and intercoolers. The fin stamping machine is mainly used for…

Fin progressive die of heat exchanger

Mold Overview 1. This fin Progressive die is suitable for automobile radiators, household air conditioners, central air conditioners, dehumidifiers, etc. 2. It is suitable for aluminum foil with different states…

Fin manufacturing machine of aluminum Heat exchanger

Machine Outline The aluminum fin manufacturing machine is a production equipment for plate and bar heat exchangers. The market has always favored its compact body design, high operational stability, and…

Aluminum inner fin machine of oil cooler and evaporator

Machine Overview This inner fin machine can produce various high-precision fins, such as window fins and wavy fins, for evaporators, oil coolers, and bar heat exchangers. The equipment has a…

Aluminum fin machine of oil cooler and heat exchanger

Brief introduction The heat exchanger aluminum fin machine is an efficient production equipment with a unique design. The cam drives two plates to move up and down. It is the…

HVAC fin machine working video

HVAC fin machine Technical Parameter

| No. | Parameter | Value |

| 1 | Motor Power | 5.5kw |

| 2 | Die Height | 200-270mm |

| 3 | Slide of Stroke | 40mm |

| 4 | Overload Protect Type | Hydraulic |

| 5 | Angle Display | Pilot Pin Digital Mode |

The advantages of HVAC fin machine

- Intelligent control system

The pointer of the stamping machine is displayed on an electronic screen, which not only accurately shows the position of the machine’s slider but also automatically stops working for any illegal operation and displays fault codes on the touchscreen.

- Application of multi-size fin molds

This high-speed fin machine can install various fin molds of different sizes to produce heat exchanger fins of different shapes and functions. Its diversified and widely used design can meet customers’ diverse requirements.

- Efficient production capacity

This fin machine has multiple independent parts assembled, such as a stamping machine, feeding machine, storage machine, lubricating oil device, etc., which form a fully automatic production line to improve work efficiency. Its fastest production speed is about 280 presses per minute.

- Powerful power output

This stamping machine uses compressed air as the main driving force and a 5.5kw motor as auxiliary power. The combination of the two outputs powerful power, with a pressing force of approximately 45 tons per press.

Plate and bar fin-making machine working video

Plate and fin-making machine Technical Parameter

| No. | ITEM | DATA |

| 1 | Fin pitch | 1-10mm |

| 2 | Fin materials | aluminum & copper |

| 3 | Fin height | 1.5-12mm |

| 4 | Max speed | 144 times / S |

| 5 | Overall size | About 155*76*168cm |

| 6 | Machine weight | About 1550kg |

The advantages of machines

1, It can automatically produce

These high-speed fin machines are set up to produce continuously without human supervision. When the output meets the set value, the machines will automatically stop

2, Mold replaceable design

This design can replace molds at a low cost according to different application scenarios, meeting the requirements of different customers

3, Application of multiple raw materials

Both machines can produce various metal raw materials, such as copper, iron, stainless steel, aluminum, and titanium alloys

4, Multiple sizes of arrangement

These machines can produce fins of various sizes arranged in one mold, and engineers only need simple settings, which is very friendly for factories with multiple-size requirements.

5. Upgradeable control device

The communication between the machine’s touch screen and the PLC adopts a professional-grade wire harness and reserves an output and input port for linkage production with other machines. or it can also be upgraded to Industry 4.0 in the future.

wechat

wechat