In high-temperature vacuum brazing furnace, the metal honeycomb carrier of an automotive three-way catalytic purifier was brazed in a vacuum.

The molybdenum screen of the furnace liner was deformed and cracked in a short time. The morphology and chemical composition of crack

ed molybdenum screens in high-temperature vacuum brazing furnaces were compared before and after use.

The results show that the reason for the accelerated deformation and cracking of the molybdenum screen is the deposition of nickel-based filler metal on the surface of the molybdenum screen.

The deposit changes the microstructure and physical properties of the molybdenum screen. Based on this, the design points of the molybdenum screen for a high-temperature vacuum brazing furnace are put forward.

In the process of using a high-temperature vacuum brazing furnace to braze the metal honeycomb carrier of a three-way catalytic purifier in the automobile industry, a large number of nickel-based brazing filler metals are volatilized,

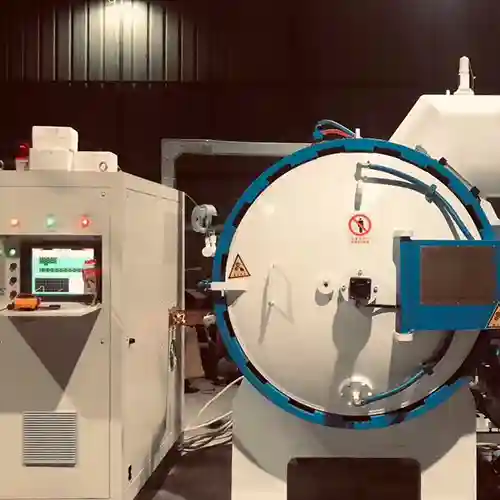

high temperature vacuum furnace

some of them are pumped out by the vacuum unit of the vacuum brazing furnace,

and a considerable part of them are deposited on the heat insulation layer of the furnace,

mainly the first layer of molybdenum screen facing high temperature is obviously deposited. A large amount of nickel-based solder deposits make the molybdenum screen of high-temperature vacuum brazing furnace appear deformation,

cracking and other failure forms and the time is short. Generally, the molybdenum screen needs to be replaced in about one year.

In the vacuum brazing process of the metal honeycomb carriers of a three-way catalytic purifier, the molybdenum screen of the furnace liner will deform and crack in a short time.

The morphology comparison and chemical composition analysis of the cracked high-temperature vacuum brazing furnace molybdenum screen were carried out before and after use.

The results show that the reason of the accelerated deformation and cracking of the molybdenum screen is the deposition of nickel-based filler metal on the surface of the molybdenum screen.

The deposit changes the microstructure and physical properties of the molybdenum screen.

Based on this, the design points of the molybdenum screen for high temperature vacuum brazing furnace are put forward. In the high-temperature vacuum brazing furnace,

once the molybdenum screen used for thermal insulation appears deformation,

cracking and other failure forms, it will cause the furnace lining of the high-temperature vacuum brazing furnace to leak heat and heat preservation failure,

Test method

Through visual observation of the appearance and crack morphology of cracked molybdenum screen in high temperature vacuum brazing furnace,

the composition of molybdenum screen with solder deposit after use was tested, analyzed, and compared, and on this basis, the causes of molybdenum screen cracking were analyzed.

The components of the samples were analyzed by the universal multi-matrix spark direct reading spectrometer of Germany OBLF QSN750.

Test results and analysis

The two molybdenum screen samples submitted for inspection are taken from the same molybdenum screen block which has been used for two years.

One of them is without sediment (the black box indicated by the arrow in Figure 2 is the interception position),

and the surface of the other piece is covered with a solder deposit. Figure 2 shows a partial picture of the front molybdenum screen.

Carefully check the cracked molybdenum screen before cutting,

the solder deposit is only covered on the side facing the furnace temperature zone, and there is no solder deposit at the overlap of the molybdenum screen (the arrow indicates the black box).

Using the vernier caliper,

the thickness of the molybdenum screen coated with the solder deposit is 0.1 mm higher than that without the solder deposit. Through visual observation of the cracked molybdenum screen,

it can be seen that the solder deposits are layered and the surface roughness

of the two parts is obviously different.

Cause analysis of molybdenum screen cracking in high temperature vacuum brazing furnace

sample composition analysis

The two molybdenum screen samples submitted,

for inspection were taken from the same molybdenum screen block which has been used for two years.

There was no solder coating on sample 1 and solder coating on a sample

The chemical composition analysis results of samples are shown in Table 1.

From table 1 It can be seen that the change of impurity content in sample composition: in sample 1 (no solder-coated molybdenum sheet),

high temperature vacuum furnace

the molybdenum content is significantly higher, the impurity content is less, and some metal impurity components such as manganese and nickel content are 0,

in sample 2 (molybdenum sheet with filler metal coating),

the mass percentage of molybdenum content is reduced,

the impurity content is doubled, and the metal impurities such as manganese and nickel content that are not contained in the original molybdenum screen are also found The increase is obvious.

According to the analysis of impurity sources,

liquid nickel-based brazing filler metal which is widely used in the vacuum brazing process of metal honeycomb carrier of three-way catalytic purifier is the main source.

wechat

wechat