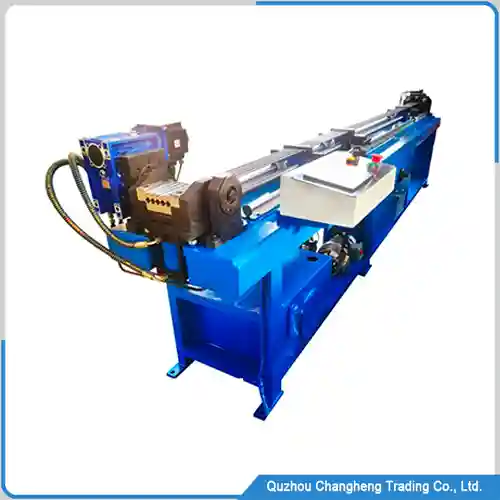

Product Introduction

This is a Hydraulic bender machine of copper tube for the HVAC industry, mainly used for bending copper, aluminum, and other metal pipes. The machine is designed for highly specialized manufacturing to ensure the tube is bent into a U shape with accurate dimensions.

Our new generation of machines is driven by servo motors, which can freely set the bending angle and molding time. This improves production efficiency and makes the output smoother and of higher quality.

To meet users’ more choices, we have kept this hydraulic-driven device.

Application area

The hydraulic bending machine is a necessary equipment in the HVAC manufacturing industry.

In addition to the copper pipe of the heat exchanger,

The machine can also bend other metal pipes, pipes in automobile air conditioning systems,

Tubes that need to be bent in other fields, etc.

| ITEM | DATA |

| Pipe type | hairpin type |

| Power drive | hydraulic |

| Workstations | 4-8PCS |

| Production type | automatic |

| Machine brand | CHANGHENG |

Hydraulic bender machine advantages

1, Multi-workstation: The bending machine has been designed with multiple workstations to bend multiple copper pipes simultaneously, thereby improving production efficiency.

2, Power saving: Due to the use of hydraulic systems to drive bending tools, the Hydraulic bend machine is very energy-efficient. This allows this type of machine to save energy costs while working for extended periods of time.

3, Rapid production: The bender machine has high precision and efficiency, thus enabling rapid production.

4, Fully automated production: This equipment can achieve fully automated production. This means the machine can automatically complete all tasks, from bending copper pipes to completing production. This will significantly improve production efficiency and reduce manual errors.

5, Customized product dimensions: We can customize production dimensions to ensure that the size and shape of bent copper pipes meet specific requirements.

wechat

wechat