Product Description

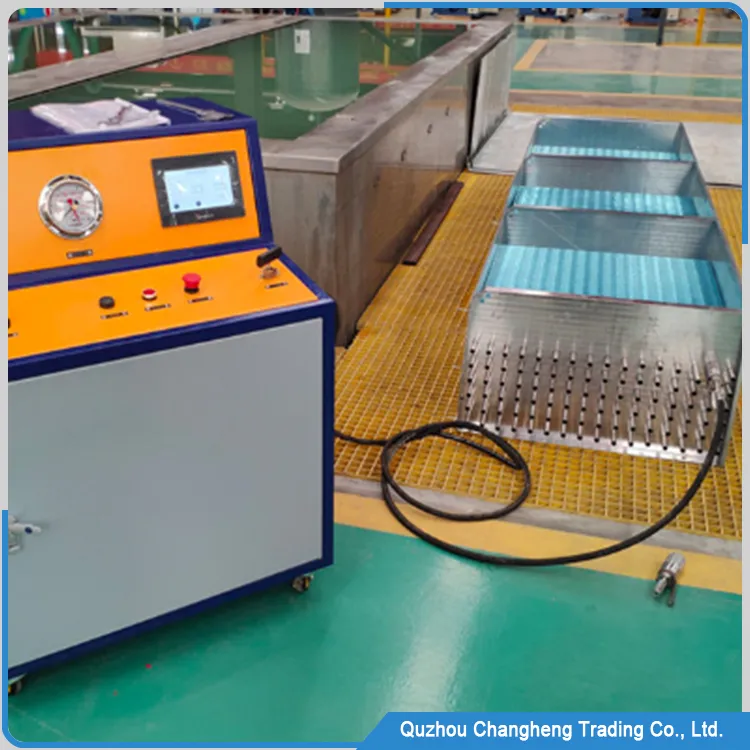

The hydraulic pipe expander is one of the most important equipment in industrial heat exchanger production. It injects tap water into the inside of the tube and expands it to the required size by increasing pressure so that the fins and tubes of the heat exchanger are tightly combined

The internal design of this device is compact, with two booster pumps working together and a maximum pressure of up to 80mpa. Whether your pipe material is stainless steel, aluminum, or copper, engineers only need to adjust the working pressure of the machine, and it can easily expand the pipe

Hydraulic pipe expander Machine parameters

| ITEM | DATA |

| Expansion medium | Tap water |

| Power supply | 220V/50-60hz |

| Usage power | 24V |

| Pipe material | aluminum copper SS304 |

| Pipe length | any size |

| Pipe diameter | customized |

| Machine packaging | wooden box |

Hydraulic pipe expander machine characteristics

- Powerful power

The hydraulic expansion equipment has two booster pumps that provide powerful power and can expand any soft metal pipe.

- Any length of pipe

Does the machine have any requirements for the length of the tubes? It can expand any length of heat exchanger tubes.

- Price of hydraulic tube expanding machine

Compared with other types of hydraulic pipe expander machines, this machine has an absolute advantage in price.

- Simple operation

The hydraulic expansion machine has a touchscreen control, allowing users to view various operating parameters intuitively. Average production only requires pressing a button to complete all the work.

- Energy saving

This machine only requires 24V voltage to operate, and its energy consumption can be ignored

Work and principle

This hydraulic pipe expander increases sufficient pressure to expand the pipe. Its working principle is to install specialized sealing tools at both ends of the pipe. One tool is connected to the machine and injected with tap water. The booster pump of the machine applies pressure, and when the pressure is sufficient, the metal pipe will expand.

After the pipe expands, the machine will release pressure, and the worker needs to remove two sealing tools. The entire expansion process is over.

This machine’s booster pump requires compressed air to drive and has a maximum output pressure of 80mpa. Users can set different working pressures based on the characteristics of the metal pipe.

wechat

wechat