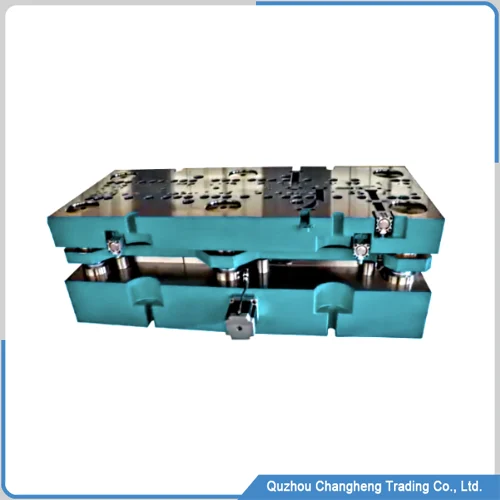

Progressive die Overview

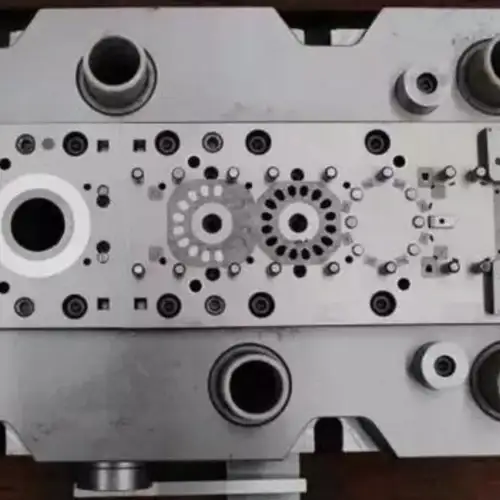

This Iron core progressive die for continuous high-speed production and can significantly improve production efficiency.

The mold is usually equipped with a servo motor, which allows for precise control of the mold’s movement, thereby producing a rotating iron core.

In addition, the mold includes automatic feeding and discharging mechanisms, further improving production speed and automation levels. This mold can adapt to the production of motor cores at different heights and has good adaptability and flexibility.

The design of this mold aims to achieve efficient and high-precision production while reducing labor intensity, and production costs, improving product quality and meeting the needs of the modern motor manufacturing industry for efficient and automated production.

Iron core progressive die data

| No. | ITEM | DATA |

| 1 | Core size: | reference design |

| 2 | Production type: | continuous |

| 3 | Appearance color: | green |

| 4 | Workstation: | 1-6 optional |

| 5 | Delivery time: | fastest 45 days |

| 6 | Material thickness: | 0.1-1.5mm |

| 7 | Foil material: | iron |

| 8 | Core height: | freely controlled |

Iron core progressive die advantage

The advantages of motor core molds include:

1, High efficiency:

Specialized molds are designed for continuous production, enabling high-speed operations, significantly improving production efficiency, and meeting the needs of large-scale production.

2, High precision:

The mold precisely controls the size and shape of the iron core, ensuring the accuracy and consistency of the product.

3, High degree of automation:

The mold can be integrated with an automatic feeding device, reducing manual intervention, reducing labor intensity, and improving production safety.

4, Stable quality:

Due to the high precision of the Iron core progressive die, it can ensure that each produced iron core has the same quality standard, reducing the scrap rate.

5, Material saving:

Mold design optimization can reduce material waste and improve material utilization.

6, Easy to maintain:

The mold design emphasizes ease of operation and maintenance, reduces downtime, and improves equipment availability.

Iron core progressive die video

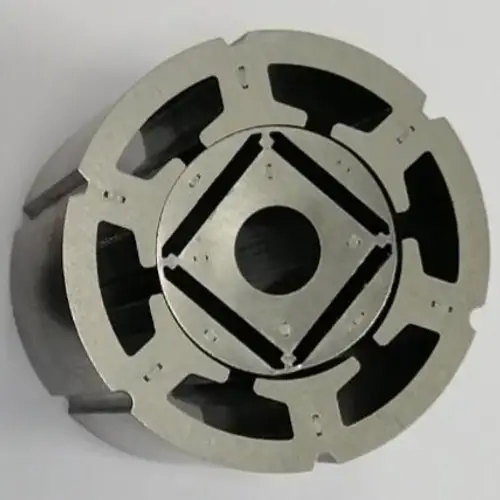

The application of this mold

- Car wiper motor

- Car radiator fan motor

- Car window glass lifting motor

- Brake pump motor

- Air suspension motor

- Automatic curtain motor

- Other small-sized motors, etc

wechat

wechat