A new type of louvre fin production equipment, the Louvre Fin Machine, has been developed to meet market demand.

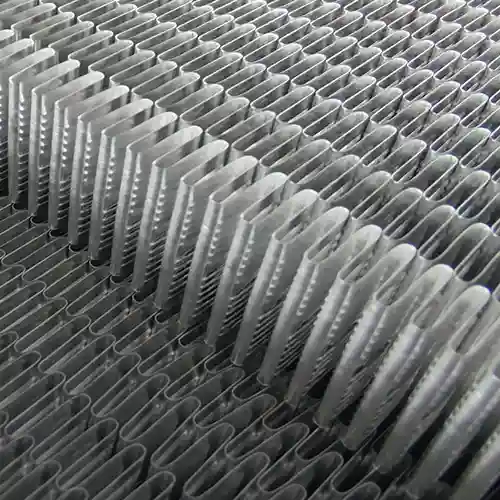

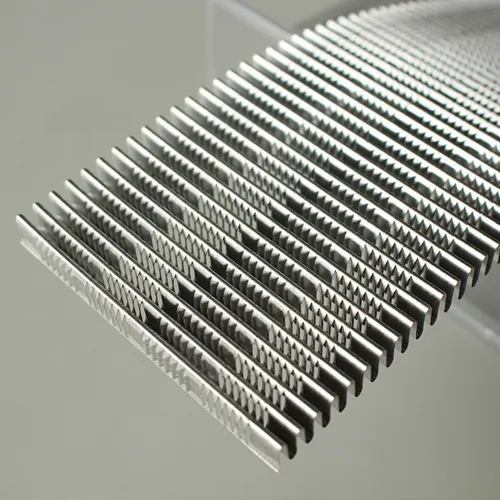

This machine is mainly used for producing louver fins for automotive engine radiators and condensers in automotive air conditioners,

The main features of this equipment include fast production speed, precise length cutting, fully automated unmanned production, and the ability to produce louver fins of different widths using a combination of roller blades.

louvre fin machine characteristic

1. The fast production speed of the Louvre Fin Machine is one of its major characteristics. Compared with traditional machines, its production efficiency is greatly improved. Can produce 80-120 meters per minute

It adopts high-precision processing technology and an automated control system, which can quickly produce a large number of louver fins.

This enables manufacturers to complete orders faster and improve production efficiency.

2. The Louve Fin Machine’s main feature is its precise length cutting. In producing louver fins, the Machine can be precisely controlled by servo motors to ensure that the length of each fin is consistent.

This helps ensure the core quality of radiators and condensers while reducing unnecessary waste and costs.

3, Louvre Fin Machine’s fully automated unmanned production is also one of its essential features. This machine can automatically complete all processing processes,

from the input of raw materials to the output of louver fins, without manual intervention.

This significantly improves production efficiency and reduces production costs.

4, Louvre Fin Machine combination roller blades can produce louver fins of different widths, which is also unique. This machine can quickly produce fins of different widths without replacing any rollers.

This allows manufacturers to produce different types of radiators without additional roller cost investment, flexibly adjusting product specifications and dimensions and improving market competitiveness.

Technical Parameter

| ITEM | DATA |

| fin materials | Aluminum & copper |

| Fin height | 4.5 – 12 mm |

| fin length | Any size |

| Feeding speed | 120 meters/minute |

| Cutting speed | 100 times/minute |

| Cutting drive | Pneumatic |

| Length control | servo motor |

wechat

wechat