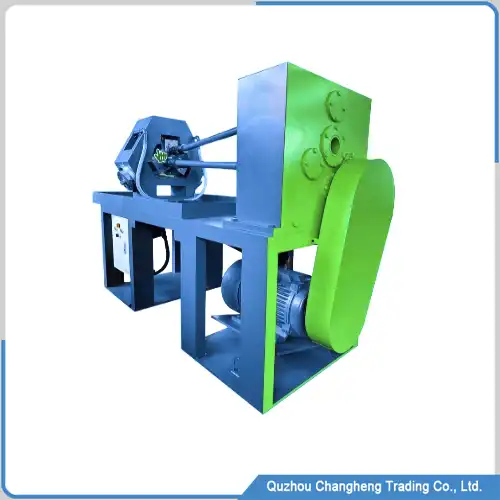

Machine Overview

The low-fin tube machine is the equipment used in the heat exchanger industry. It is driven by an electric motor, which rotates the spindle and rolls the mold to extrude metal tubes into low-fin tubes.

This device has a sturdy structural design, with three rollers squeezing to control the low fin’s quality effectively. Additionally, the device has a built-in coolant circulation system to effectively cool the heat generated by the friction between the roller mold and the metal tube.

The mold of the low-fin tube production equipment can be freely replaced, and different molds can produce different sizes of fin tubes. This flexible design can meet the needs of different customers

Low-fin tube machine data

| No. | ITEM | DATA |

| 1 | Tube diameter | 8-65mm |

| 2 | Motor voltage | 11kw |

| 3 | Tube materials | copper iron aluminum |

| 4 | Appearance color | default green |

| 5 | Lubrication device | built-in |

| 6 | Delivery time | 35 days |

| 7 | Fin size | Follow design |

| 8 | Power supply | 380V/50Hz |

Equipment advantages

1. Built-in cooling system

The coolant tank has a filtering device that isolates and circulates impurities in the coolant. The coolant is used to cool the heat of the roller mold, ensuring its service life

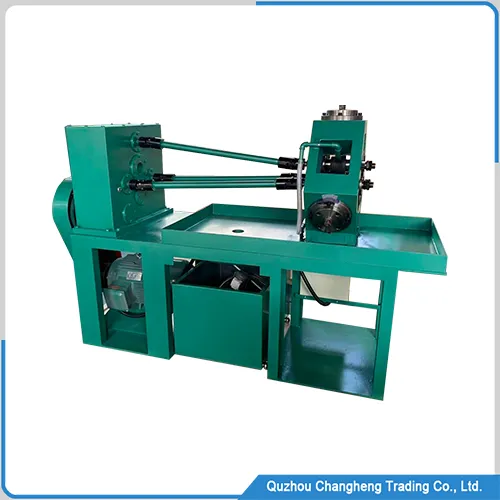

2. Simple control of machine operation

This low-fin tube machine only has 3 control buttons, making it very easy to control the entire equipment. Workers only need simple training to start working

3. The machine has strong power

This machine has an 11kw electric motor as the main drive; the maximum speed is 1350 revolutions per minute, with powerful power output, which can meet your production needs whether you are producing low-finned tubes made of copper, aluminum, or iron materials

4. Free control of tube length

The two sides of the mold of this machine are hollow. In theory, you can produce metal pipes of any length, but it is recommended that the maximum length does not exceed 6 meters.

Low fin tube machine working video

Low fin tube machine Customized services

- Machine appearance color: If special machine colors need for the machine’s appearance, please provide a color chart, and we will meet the personalize needs of customers.

- Roller mold size: We accept customized services for roller molds. You only need to provide size requirements such as fin height and fin spacing, and we can meet your requirements.

- Workbench production: Finned tubes require a dedicated workbench to achieve automated production. We can make such workbenches for you according to your production needs.

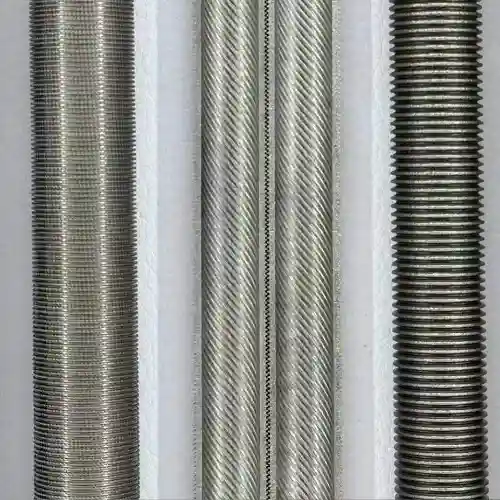

- Diversified molds: This equipment can produce various air tubes, such as low fin tubes, spiral tubes, copper fin tubes, aluminum fin tubes, etc. You only need to provide the design of the finned tubes, and we will provide diversified mold customization services.

Other tube fin machines

Extruded fin tube making machine suppliers in china

Machine Description extruded fin tube making machine to lining aluminum tubes of different specifications with copper tubes or steel tubes. The fins are formed by rolling and laminating with the cutter in the unit, to…

Finning tube machine of Heat exchanger

Product Description The extrusion aluminum finning tube machine adopts the form of an aluminum tube as the base tube, and after being extruded by the machine, it forms a spiral shape of the fin, which…

Fin tube rolling machine at best price in china

Machine Outline This fin tube rolling machine specializes in producing two metal spiral fin tubes with different diameters. It can produce special finned tubes for bimetallic heat exchangers This machine adopts a 3-axis rolling roller…

Install and debug

This low fin tube machine must be connecte to a three-phase power supply. Depending on the country’s power supply, we will adapt different motors to ensure that the machine can operate normally,

The first time running the machine, it is necessary to check the direction of rotation of the motor. If the direction of rotation of the motor is incorrect, then two of the power cords need to be replace.

This fin machine only has four button switches: the operation and stop of the machine, the operation and stop of the coolant water pump motor, and simple training for workers to use this machine.

We will provide 500 milliliters of coolant sample; please use the same quality of coolant, as extrusion production generates a large amount of heat, and ordinary quality coolant cannot completely cool, which will result in poor production quality.

Q & A

A: Yes, it can produce materials such as copper, iron, aluminum, etc.

A: This depends on the spacing of the fins, usually producing 300-500 meters per hour.

A: We have another machine that can produce pipes of two types of metals.

wechat

wechat