Radiator Machine Overview

Mechanical radiator machine require many different types of equipments, usually requiring multiple steps to complete a radiator. In this production process, many machines are required to participate in this work,

The following are the corresponding machines required to produce a mechanical radiator:

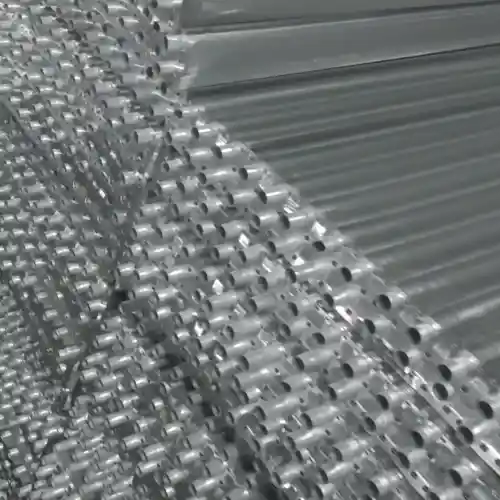

Tube expander machine

This type of machine enlarges the tubes of the aluminum core, tightly fixing the aluminum tubes and fins together, thereby providing a good cooling effect for the entire aluminum core. This machine is usually driven by hydraulic pressure, but with the development of industry, the equipment is driven by servo motors,

A mechanical radiator machine driven by a servo motor can accurately control length and dimensional accuracy, reduce noise, and save power. Compared to hydraulic-driven equipment, servo motor drive has many advantages, but it is also more expensive

You can view this video to learn more about the details of this machine

Mechanical radiator machine of Fin punching

This machine is mainly used to produce aluminum fins for radiator cores. It is a fully automatic production line, and the entire production process does not require workers to supervise the machine. Its production speed is 280 presses per minute, which can provide good production efficiency for the factory,

When the production of aluminum fins is completed, a worker needs to insert the aluminum tube into the middle of the hole to form an aluminum core

You can watch this video to learn more about the production process of fin punching machine

Flaring machine

The function of this machine is to install the header plate on the aluminum core and secure it, The latest generation of this machine adopts servo motor drive, There are many advantages of servo motor drive mentioned above, which will not be elaborated here. Its disadvantage is that it will be more expensive

This mechanical radiator machine is indispensable throughout the entire production process, as the assembly process of the head plate and core is crucial. A small mistake can lead to leakage of the entire radiator. Therefore, when choosing this expansion machine, you must pay attention to the quality of the machine rather than its price

You can watch this video to learn more details

Plastic tank installation machine

This device is also a key machine, its main function is to assemble plastic tanks and aluminum cores together. The machine intelligently avoids and presses it in place. A servo motor drives this device, and the cylinder presses the head plate

Our latest generation of machines can press 4 sides at once, further improving production efficiency

You can view this video to learn more about the details of the machine

Leakage testing machine

This is a leakage testing device, whose main function is to test whether there is a leakage in the heat sink. It is driven by a 220V power supply and requires a compressed air pressure of 0.4 MPa during the testing process. The device has two workstations, which means you can test two aluminum heat sinks simultaneously

It has two 7-inch touch screens for setting test parameters. You can set different test parameters for different types of radiator,

You can check out this video to learn more details

Mechanical radiator data

| ITEM | DATA |

| Radiator type | Mechanical type |

| Fin material | Aluminum |

| Fin thickness | 0.08mm |

| Header plate | Iron |

| Tube material | Aluminum |

| Tank material | PA66-GF30 |

| Gasket material | EPDM |

Mechanical radiator machine

These devices are the entire production line for instrument radiators, and each machine can be missing. If you are a new factory, you also need an air compressor, packaging equipment for radiators, etc.

In the following video, we are producing Rada 2108 radiators in an old factory in China. You can take a look at it and understand the entire radiator production process,

wechat

wechat