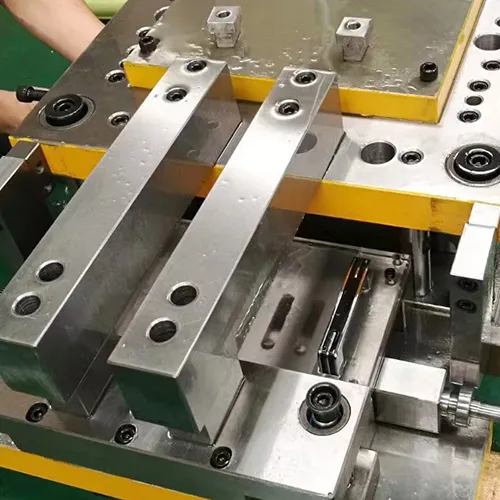

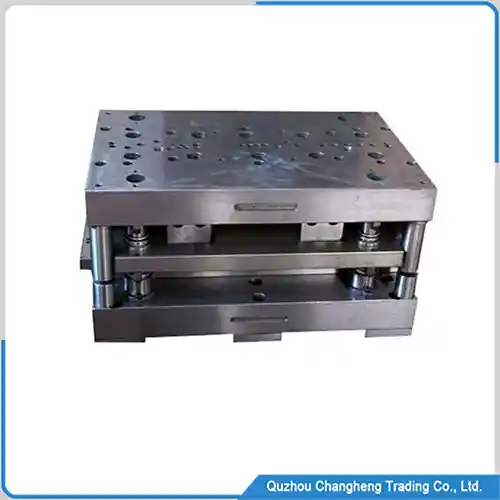

Mold Overview

We provide a wide range of customized metal stamping mold services specifically tailored to the needs of industrial applications. Our team can design and manufacture molds suitable for various stamping types based on customers’ requirements. We have professional technical capabilities and rich practical experience to provide you with the most appropriate solutions, whether it is the need for continuous stamping molds to achieve mass production or high-speed and precise fin progressive molds to meet high standards of machining accuracy. We aim to ensure molds’ reliability, durability, and high efficiency to meet your production needs and enhance your competitiveness.

More metal stamping mold

Why choose our metal stamping molds

Easy to maintain:

A well-designed mold is easy to maintain and helps maintain production stability and continuity.

Durability:

High-quality stamping molds are made of wear-resistant materials and have a long service life.

Customization:

Stamping molds can be customized to meet special production requirements, including different sizes, shapes, and functions, according to the customer’s needs.

High precision:

Stamping molds can accurately manufacture the required parts, ensuring that the size and shape of the finished product meet strict tolerance requirements.

Technical parameter of metal stamping mold

| ITEM | DATA |

| Production: | Metal |

| Product: | Customized |

| Category: | Continuous,&Single |

| Guide pillars: | Multiple |

| Application: | Industrial |

| ITEM | DATA |

| Board material: | RC12 & SK51 |

| work type: | Stamping |

| Needle brand: | LIDA |

| Color: | Green |

| Delivery time: | 45 days |

Metal stamping mold working video

Support and Services of metal stamping mold

We accept any stamping mold and design and manufacture the most reasonable mold based on the structure and shape of your stamping machine and parts.

Everyone knows that stamping molds may experience wear and tear during production. To extend their service life, molds usually need to replace parts. I can supply stamping mold parts,

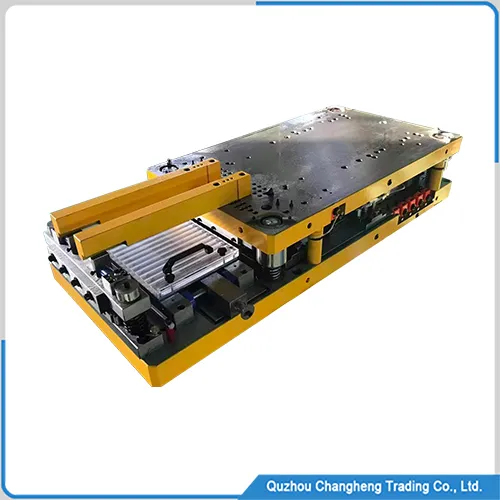

Our most professional fields are stamping molds for automotive radiator parts and high-speed fin molds for heat exchangers. Because we focus on these two industries, we are very experienced.

The raw material of metal stamping mold

External mold plate: EN C45

Internal mold plate: EN C45

Mold core: Cr12MoV

Stripping plate: EN C45

Hole sleeve: SKH51

Concave parts: Cr12MoV

Convex parts: Cr12MoV

Mold Spring: 50CrVA

Needle punching: SKH51

Central guide pillar: SKH11

Ordinary guide column: SKH11

Horizontal sales: 50CrVA

Screw: Cr12MoV

Manufacturing technology

The manufacturing technology of each metal stamping mold differs. We will introduce its manufacturing technology using the fin die of a heat exchanger as an example.

Step 1

Design the mold’s structure and stamping process based on the product’s special characteristics, optimize the mold design according to the customer’s stamping machine type, and meet the product’s production technology requirements.

Step 2

To create a blueprint for the processing of each stamping die component, the production department needs to purchase the raw materials for the mold,

Step 3

The mold manufacturing factory roughly processes each part according to the blueprint, then performs tight machining and manufactures the required holes and special structural shapes.

Step 4

Assemble all the metal stamping mold parts, some of which may require further optimization during this process. Once the mold assembly is complete, testing can begin.

Step 5

After testing the mold and improving and polishing it to fully meet the design requirements, the stamping mold can be delivered to the customer.

Q & A

A: Of course, this is our specialized field.

A: You need to provide samples of parts or D3 design.

A: Stamping molds usually take 300000 times or a year.

wechat

wechat