Product Description

This is an industrial metal tube cutting machine. It is driven by multiple servo motors, which can realize fully automatic, unattended production. The machine can also be intelligently making by setting the length and output of the tube through a touch screen.

The material of the saw blade of this machine is cemented carbide, which has high hardness and good cutting performance. It can be applied to tube cutting of various materials, such as aluminum and copper.

When the metal tube is cut, the blade and the tube will not come into contact. This special technique is uses in this machine, so the cut metal tube will not have extra burrs.

Metal tube cutting machine Technical Parameters

- Raw Material: aluminum or copper

- Wall Thickness: 0.1-10mm

- Max Width: 600mm

- Weight Of Raw Material: 6-8 tons

- Inner Diameter Of Finished Material Roll: 300mm

- Outer Diameter Of Finished Material Roll: 800-1000mm

- Voltage: 4.5kW

- Power supply: 380V/50Hz

- Outline size: 260 * 100 * 150cm

- Cutting blade material: carbide steel

- Table size: 80 * 120cm

- Table height: 80cm

Metal tube cutting machine working video

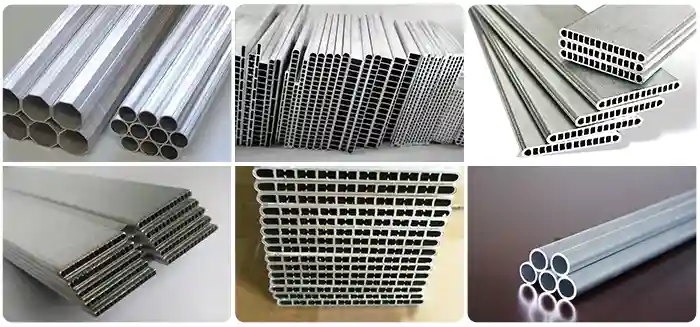

The application scenario of this machine

1. Aluminum radiator: The automotive industry uses aluminum radiator tubes with a wall thickness of 0.28mm, which this machine can cut perfectly.

2. Microchannel aluminum tube: This tube is usually a key part of the automotive air conditioner condenser

3. Heat exchanger bar and bar: laminated type of heat exchanger aluminum parts, it requires high precision cutting, this machine is very suitable

4. Microchannel copper pipe: Some special fields want to use microchannel copper pipe, and this machine can cut it without burrs.

5. Connecting pipes for air conditioning systems: These tubes need to be processed twice after cutting, and they require high precision, so this machine is the best production tool.

The above usage scenarios are just an example, and there are many parts. This metal cutting machine can cut perfectly. If you are unsure which type your part belongs to, contact our engineers for help.

Metal tube cutting machine features

1, The machine adopts a scientific structural design, and the sliding parts are equipped with linear slides, which can achieve a maximum load of 6-8 tons of raw materials.

2, the control system has a touch screen as a human-machine interaction; visual operation logic helps engineers quickly grasp the use of this tube-cutting machine.

3, The cutting blade is made of carbide steel, which can almost ignore the problem of blade wear when cutting aluminum and copper materials.

4, This machine focuses on cutting high-precision parts, with almost no burrs in the cutting position.

5, Long-term cutting will cause the blade to overheat, so this machine has an automatic lubrication device, which regularly sprays lubricating oil to the blade, and this process does not require manual participation.

Optional advanced features

This metal cutting machine will generate aluminum chips during work, and some cities have high environmental protection requirements so we can provide options, such as a vacuum adsorption machine.

It can absorb all the aluminum chips and maintain a high degree of cleanliness for the factory’s workshop.

The machine and the cutting machine are centrally controller. When the cutting machine runs, the vacuum adsorption starts, and when it stops, it also stops working. This control method can save electricity in the production process.

Final summary

This metal-cutting machine is a key tool in industrial production. It is fully automatic and can cut various metal tubes, bars, and plates. It has a wide range of applications in the refrigeration industry.

If you are looking for a machine to cut metal materials, this metal cutting machine is a good choice. You can also contact our engineers for more details.

wechat

wechat