Product Description

This oil cooler fin machine is specialized processing equipment, mainly used to produce fins for heat exchangers and oil coolers.

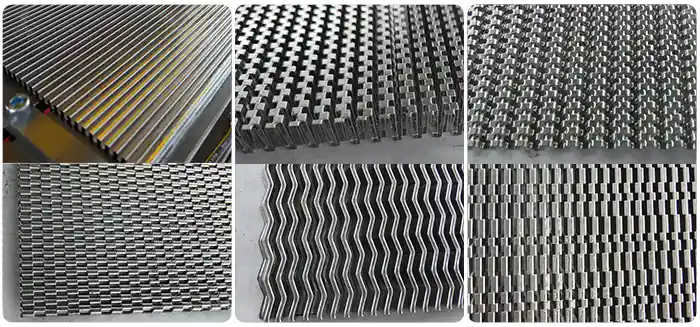

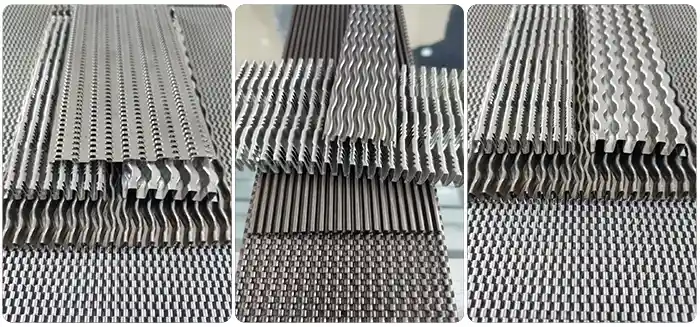

This fin is a key component of the heat exchanger. Its shape can be sawtooth, wavy, and so on, in different types,

Over the past few years, we have been dedicated to improving the production speed of this machine and the smooth output of our products. We have listened carefully to our customers’ opinions and actively solved problems in the production process. Now, this machine has fully realized fully automatic production.

Our fin machine has steps such as feeding, punching, forming, and cutting, which make up a complete production line. The molds are designed independently, and users can produce various shapes of fins.

The common fin shapes include a straight fin, sawtooth fin, porous fin, corrugated fin, louver fin, etc.

This fin with heat transfer function has been widely uses in automobiles, ships, air conditioners, compressors, construction machinery, mining machinery, aviation, military industries, and the hydraulic oil cooling industry.

Oil cooler Fin machine features

- The main shaft is designed to be centered.

The main shaft of the equipment is located in the center, which reduces the loss in the process of torque transmission. It can smoothly output strong power, and the maximum torque can reach 3.5 tons.

- High precision.

The Oil cooler fin machine’s workbench has 4 guide columns, and the flatness of the mold table in the production process is higher than that of similar products, thus ensuring the stability of the machine’s performance.

- Automatic lubrication system.

This equipment has a unique automatic lubrication system that lubricates each guide post and bearing to reduce machine wear and extend its lifespan.

- Stepless adjustment.

It can achieve stepless adjustment, breaking through the limitation of insufficient gears in traditional mechanical speed adjustment.

- Easy to maintain.

We have optimized the structure’s design, and the machine tool’s components have been thoroughly simplified, making maintenance easier and reducing maintenance costs.

Oil cooler fin machine Technical Parameters

- Power supply: 380v/50Hz

- Voltage: 5.5kw

- Maximum width: 300, 450, 600mm are available for selection

- Materials: aluminum, copper, stainless steel, titanium alloy, etc

- Aluminum thickness: 0.05mm – 0.5mm

- Fin shape: sawtooth, wave, etc

- Maximum production speed: 140/min

- Lubricating oil: 32-36#

- Fin lubricant: Volatile oil

- Fin mold: replaceable design

- Appearance: Color is optional

- Dimensions: 1200 * 1500 * 1680 mm

wechat

wechat