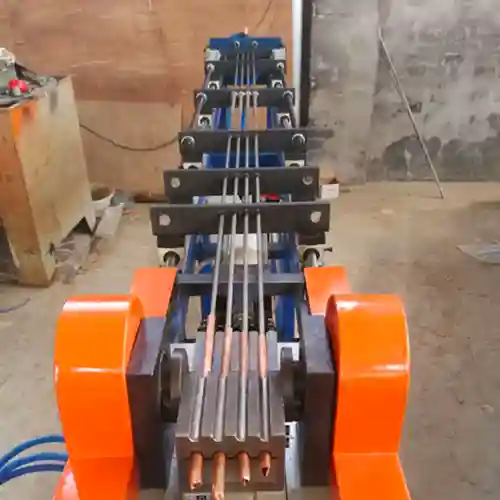

Machine Overview

The Pipe bending machine is the equipment used for processing hairpin pipes, and it is one of the key settings in the production of heat exchangers and condensers. With the development of industry and the popularization of servo motors, the performance and accuracy of this equipment have been upgraded

Working principle of pipe binding machine

The hairpin bending machine is one of the essential equipment in the heat exchanger factory. It can bend pipes of different soft metals, such as copper, aluminum, stainless steel and other materials

Now let’s introduce its working principle

1, Firstly, the copper pipes of the coil need to be straightened and cut, and the length of the pipes must be consistent. Workers need to insert these pipes into the tools of the pipe-bending machine

2, Press the start button of the machine or the foot switch, and the machine will bend the copper tube into a hairpin shape. It automatically completes the bending process

3, When the copper pipe is bent, the unloading device of the machine will push out the pipe, and then the lubrication device will spray lubricating oil, waiting for the next cycle

Pipe bending machine Part Brand

| part name | brand |

| PLC | Mitsubishi |

| Pneumatic accessories | SMC |

| Servo motor | Mitsubishi |

| Electrical accessories | Schneider Omron |

| Touch screen | Delta |

Advantages of pipe bending machine

- The high degree of automation

The Tube bender machine adopts PLC centralized control, realizing automated production of bending and unloading processes

- High precision

The bending axis servo motor drive of this device can accurately control the bending angle, thereby ensuring the accuracy of the hair clip tube

- High production efficiency

The pipe bending machine adopts a multi-station design and can simultaneously bend 4-8 copper pipes. Compared to single-station equipment, Its production efficiency has significantly improved

- Energy saving

Thanks to the servo motor drive, compared to hydraulic-driven machines, it can significantly save electricity

Technical Parameter

| ITEM | VALUE |

| Pipe diameter | 5-12.7mm |

| Wall thickness | 0.2-0.5mm |

| Bending amount | 8 pieces |

| Bending length | 200-3000mm |

| Air source pressure | 0.5~0.6Mpa |

| Pipe central moment | 15-35mm |

| Bending speed | 12 times/min |

| Bending type | U type |

| Power supply | 380V/50Hz 3-phase |

| Total power | 7.5 kW |

Machine Video

Q & A

A: The maximum length of this machine is 3000mm, and we can customize longer sizes.

A: Our regular machine bends 4-8 pipes at a time, and we can customize the machine to bend 6 or 8 pipes.

A: Yes, this machine have touch screen and PLC control

wechat

wechat