Product Description

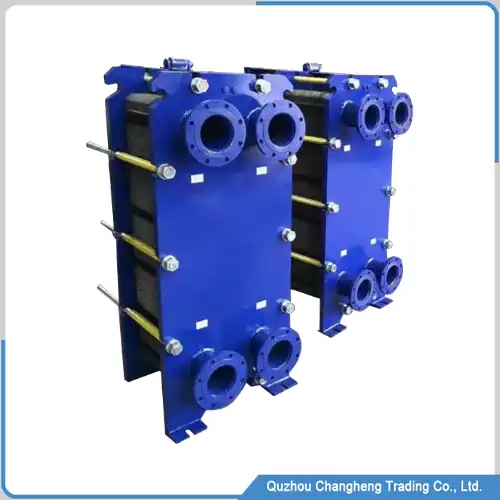

The Plate and frame heat exchanger is one of the essential products in modern industrial production. It is composed of frame, corrugated plate, sealing gasket, screws, flange and other parts. The corrugated plate is pressed and formed by a 500-ton hydraulic press, which eliminates the stress on the surface of the corrugated plate and forms a W-shaped texture. The surface error of each texture will not exceed 0.1mm. This high-precision manufacturing process can prevent the leakage of heat exchanger.

This type of plate heat exchanger is very flexible, it can increase the amount of ripple plate, easily increase the heat exchange efficiency, so it is widely useing in modern industrial production, such as ships, chemical plants, seawater desalination, food and beverage, petroleum refining, and other industries, all of which need these heat exchangers to participate.

Table of contents

- Product Description

- Plate and frame heat exchanger technical advantages

- More industrial Plate and frame heat exchanger

- Manufacturing process of plate and frame heat exchanger

- Plate and frame heat exchanger Technical parameter

- Plate and frame heat exchanger factory video

- Application area

- Why choose our Plate and frame heat exchanger?

- Q & A

Plate and frame heat exchanger technical advantages

- Scientific texture design

The unique corrugated layout design not only increases the heat transfer area significantly but also generates eddy currents when the fluid flows from the channel, achieving ultra-high heat transfer efficiency.

- Modular structural design

The frame is fixed with screws, which support flexible disassembly. You can increase the number of corrugated plates to change the thermal efficiency, or combine multiple devices to adapt to your new process needs.

- Reliable seal

The sealing gasket is made of high-quality EPDM, and its surface is coated with corrosion-resistant resistance to ensure that the two flow channels are tightly isolated. Not only that, even if a leak occurs, the fluid will only overflow, and the two media will not cross-mix.

- Multi-material supply

For different chemical industries, such as high-temperature steam, strong acid liquids, electrolytes, etc., we scientifically choose Hashi metal, titanium alloy, stainless steel and other materials to prolong its service life.

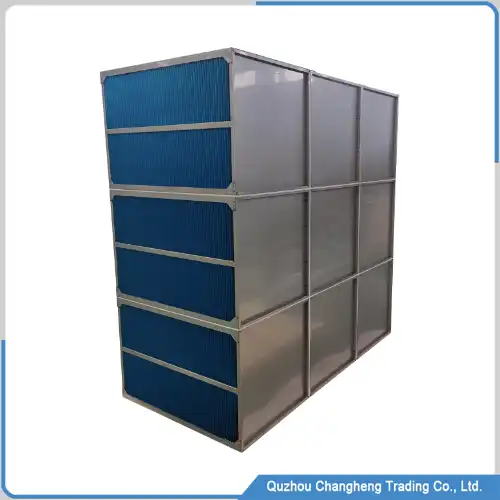

More industrial Plate and frame heat exchanger

Manufacturing process of plate and frame heat exchanger

The heat exchanger requires a variety of professional equipment and production processes to complete, and the manufacture of high-quality heat exchangers requires mastering some key technologies, such as CNC machining technology, spraying technology, and mold manufacturing technology.

Let’s briefly introduce the steps of the entire heat exchanger manufacturing process.

Frame plate

The material of the frame plate is 45-steel, and its thickness is usually 20-25mm. Large heat exchangers will use thicker materials. First, it needs a flame cutting process to cut it to the required size, and then it is ground to a flat surface on both sides. Use CNC machine tools to drill and trim excess parts.

Some special frame plates need to be welding with flanges, and then check the weld to polish it, and then perform surface spraying treatment, and the frame part is manufacture.

Corrugated plate

Pipple plate is a significant part, its quality directly affects the service life and heat exchange efficiency, so its lines must be scientifically design, using a large hydraulic press to form, cutting rounded corners and holes

The ripple plate material thickness is 0.5mm, usually stainless steel, titanium alloy, Harbin metal and other materials. Different fluid media require different metal materials to prolong the service life of the heat exchanger.

Sealing gasket

It is EPDM glue and other chemicals following the scientific proportion of mixing, and then after many stirring and extrusion to form the required raw materials, the material using a high-temperature hydraulic press to create the required size, and finally, the gasket also needs to be high-temperature vulcanization treatment.

The production of this kind of sealing gasket has strict requirements for environmental protection. There will be some dust when the material is stirred, and an odor will be emitted during high temperature forming and vulcanization.

Plate assembly

The process of assembling the sheet is critical. Workers must assemble it in strict accordance with the design requirements. Each gasket must be put flat; otherwise, leakage will occur.

Therefore, when the ripple plate core Installation is complete, it must undergo a rigorous visual inspection. Each piece of ripple plate must be marked to indicate whether it has been installed correctly. Then, the frame plate and lock the screws.

Leak test

After each Plate and frame heat exchanger Installation is complete, it must undergo a rigorous 100% leak test. Usually the pressure of the test machine is 1.8MPa, which is much higher than twice the normal operating pressure.

The sealing test method is to inject high-pressure air into the heat exchanger, hold the pressure for 10 minutes, and if the pressure remains stable, it is judged to be qualified. Then, put the heat exchanger into the water, inject compressed air, and check whether the water is bubbling.

Packaging and delivery

The heat exchanger is labeled according to the customer’s requirements, then packing and delivery to the customer, where a complete plate heat exchanger is manufactured.

Plate and frame heat exchanger Technical parameter

Maximum pressure: 1.5 MPa

Screw: m22

Nut Material: Stainless Steel

Corrugated plate pattern: V type

Corrugated plate thickness: 0.5mm

Number of corrugated plates: follow the heat exchange efficiency

Fluid channels: 2 independent

Plate Material: Stainless Steel, Titanium Alloy, Harbin Metal

Frame material: ordinary carbon steel

Frame thickness: 25mm

Gasket: EPDM

Flange size: follow the user’s design

Packing type: wooden box in line with international logistics

Delivery time: about 35 days

Plate and frame heat exchanger factory video

Application area

- textile industry

- paper industry

- Central heating

- Thermal power plant

- Boiler heating

- Oil and fat industry

- electric power industry

- Marine diesel engine

- Solar energy utilization

- chemical industry

- steel industry

- Metallurgical industry

- Machinery manufacturing industry

- food industry

- Beer production

- Central cooler

- Seawater desalination

Why choose our Plate and frame heat exchanger?

- We complete the entire production process from A-Z independently, which not only controls the size and quality of the product throughout the process, but also guarantees the production cycle and timely delivery

- Our technical team has an average working experience of 15 years, you need to provide some simple technical data, and we can design the heat exchanger you need for you, and can meet all your production needs

- To meet the increasingly stringent environmental requirements, we purchased the same spray booth as the car spray, which not only meets the strict environmental requirements, but also improves the appearance quality of the frame plate

- Our manufacturing plant has been in operation for more than 20 years and currently has more than 80 high-quality sheet molds of different sizes. Whether you are from the chemical, marine, petroleum, food, beverage, or winemaking industries, we can provide the perfect solution of The Plate and frame heat exchanger.

- If you are from the medical industry, we can use the argon arc welding process for the corrugated plate, without the need for a gasket so that the fluid heat transfer will be purer

- Far beyond the testing standards of the heat exchanger industry, we not only have high-pressure airtight testing equipment, but also perform sealing tests in purified water, and a variety of tests ensure that it will not leak in any environment.

Q & A

A: The usual delivery time is 30 days, while the delivery time for large-sized heat exchangers is 45 days.

A: Of course. We have many stamping molds that can produce a range of sizes. For more details, you can contact our engineers.

A: We strictly follow China’s mandatory service policy, and the guarantee period for this heat exchanger is one year.

wechat

wechat