Product Description

This plate bending machine is an intelligent and multifunctional bending device. No matter how complex the sheet metal parts are, it can efficiently and accurately complete them in one go.

This machine adopts a two-stage linkage pressure drive, which achieves low energy consumption during equipment operation and has strong power output.

The structural design of the plate bender machine is carried out following high-precision machine tool standards, ensuring the overall accuracy and stability of the machine tool during long-term operation.

Plate bending machine data

| No. | ITEM | DATA |

| 1 | Maximum width | 150-250cm |

| 2 | Material thickness | 3mm aluminum 2mm carbon steel 1.5mm stainless steel |

| 3 | Maximum gap | 190mm |

| 4 | Minimum radius | 1.5 mm |

| 5 | Production mode | fully automatic |

| 6 | Drive method | servo motor |

| 7 | Bending angle | 0-180° |

| 8 | Control type | Programming |

Plate bending machine advantage

- Precision control

Servo motors control the movement and rotation of metal plates, accurately controlling each size to ensure the plates’ accuracy and consistency.

- Fully automated production

Workers only need to place the board material on the plate bending machine’s workbench, and the machine will automatically recognize it. Then, according to the set steps and program, all the bending work will be completed in one go. This process is fully automated.

- Workers do not require training.

Even if you need to produce complex parts, new workers can easily operate this machine, which is the advantage of automated machines, greatly reducing labor costs and training time.

- A friendly working environment

The device does not produce noise during operation, and the height of the workbench of the machine conforms to ergonomics, so workers will not feel tired after long-term work,

Plate bending machine working video

Bending machine control system

This machine adopts centraliz control, and all bending programs are programmed on a 15-inch touchscreen. It has visual operation logic, and engineers can intuitively edit a new bending program.

To provide users with great operational convenience, we accept customized touchscreen languages, whether you need Russian, English, Spanish, French, etc,

The bending tool adopts a quick disassembly design, which greatly improves the efficiency of mold replacement. Engineers can switch from one model to another in just over 10 minutes.

Operation and safety

This plate-bending machine does not come into contact with the bending position by workers’ hands during normal production, so there is no danger.

When the engineer changes the mold, the machine can switch to safe mode. This soft-state machine has no buttons, is disabled, and has the motor turned off.

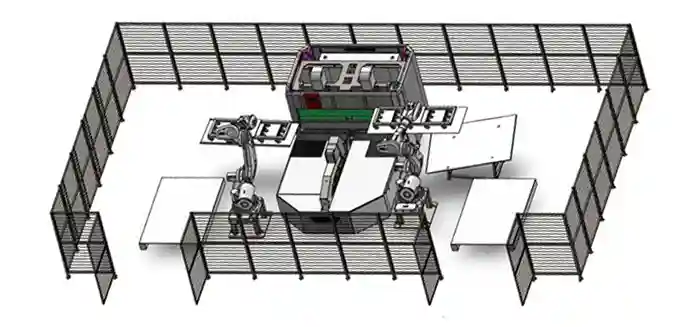

There is a mesh wall around the periphery of the machine for isolation, making it difficult for other workers to approach, so the production of this machine is very safe.

Q & A

A: It can bend aluminum plates, galvanized plates, steel plates, and stainless steel plates, but the maximum thickness cannot exceed 3mm.

A: Not included, but I can customize it for you.

A: Your metal plate material and thickness, the maximum size of the product.

wechat

wechat