Product Description

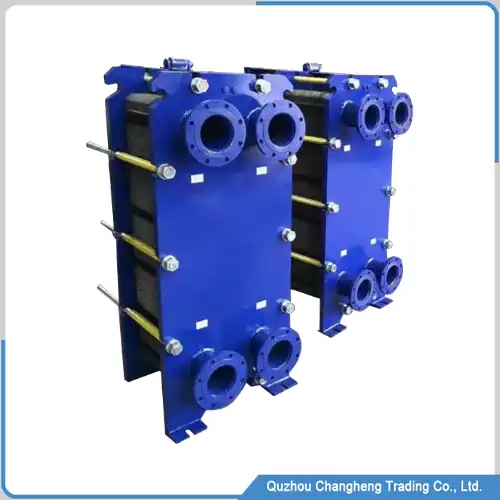

The plate-type heat exchanger is an efficient heat exchange device mainly composed of two media that transfer heat to each other. Its structure consists of multiple corrugated plates stacked together.

The gap between the corrugation plate and the corrugation plate is seal with a sealing gasket, which prevents the medium from leaking during heat transfer and ensures safety and stability,

The function of ripples is to enhance the assistance of medium flow and improve the efficiency of heat transfer.

Plate-type heat exchanger’s advantages

- Efficient heat exchange efficiency

Each sheet has ripples that cross and stack to form complex channels, causing significant resistance to the medium’s flow. This design greatly improves heat transfer efficiency.

- Easy to clean and maintain

This heat exchanger adopts corrugated plate cross-stacking, frame fixation, and screw locking. Users can easily open it and clean the internal stains and impurities, extending its service life.

- Flexible installation

Plate heat exchangers have a small volume and are lightweight, and the environment of the installation site does not constrain them. They can be placed arbitrarily without affecting their functionality and performance.

- Its application is pervasive

This plate heat exchanger type is widely used in modern industrial fields, such as seawater desalination, food, petroleum, and pharmaceuticals.

Plate type heat exchanger data

| No. | ITEM | DATA |

| 1 | Plate thickness | 0.2-0.5 mm |

| 2 | Plate material | stainless steel 304 |

| 3 | Heat exchange medium | water, oil |

| 4 | Frame material | ordinary carbon steel |

| 5 | Flange material | stainless steel |

| 6 | Structure | Stacked |

| 7 | Heat exchange efficiency | customized by customers |

| 8 | Max Pressure | 1.5mpa |

Plate type heat exchanger manufacturer video

Other heat exchangers

Plate heat exchanger for selling

Product Description This plate heat exchanger type is one of the most popular, consisting of many stacked metal plates. The edges of the metal plates are sealed with EPDM gaskets, and both ends are reinforced…

Cross flow heat exchanger production line

Production line synopsis Cross flow heat exchanger production line, as long as it is a hydraulic press driven mold,Special non-standard, customized machine, with servo motor driving to move raw materials automatically,It produces 20-30 aluminum plates…

Plate and frame heat exchanger

Product Description The Plate and frame heat exchanger is one of the essential products in modern industrial production. It is composed of frame, corrugated plate, sealing gasket, screws, flange and other parts. The corrugated plate…

Plate heat exchanger material

Corrugated board material

This component’s material is usually stainless steel 304 with a thickness of 0.5-0.6mm, and titanium alloy is use for heat exchangers with unique application environments.

Rubber sealing gasket

Its material is EPDM, which is from petroleum and processed into a sealing gasket. It is installed in the middle of the corrugated plate as a seal to prevent the two media from mixing when flowing inside the heat exchanger.

External framework

This is a regular 45 # carbon steel with a 30-50mm thick base. Larger heat exchangers require thicker frame plates, which are important components for fixing the entire heat exchanger.

Frame screws

This is a high-strength screw that fixes two frames and locks them in place, allowing the heat exchanger to withstand sufficient pressure during use.

Q & A

A: The plate heat exchanger factory is located in Shanghai.

A: Our heat exchanger warranty period is 12 months.

A: Of course, please get in touch with our engineers to obtain our board size list.

wechat

wechat