With the rapid development of modern industry, the production of aluminum fins for condensers and heat exchangers has become a highly automated and efficient industry. In this process, the continuous production of progressive die stamping has become an indispensable tool

operational principle

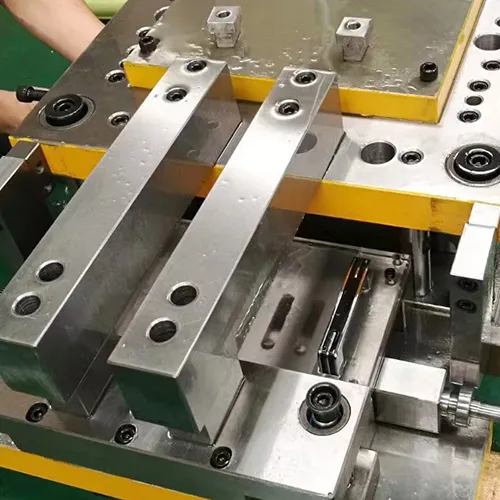

Progressive die stamping is a mold for producing aluminum foil fins for condensers, which can produce high-precision and high-quality fins on continuous production lines.

This type of mold has an automatic feeding tool. During normal and rapid production, the aluminum foil can be moved at high speed without external assistance. It is accurately placed at the pressing position of the mold and then pressed into the desired fin shape through processes such as pressing, stretching, and cutting.

During this process, multiple workstations inside the Progressive stamping die complete their respective tasks simultaneously, achieving a complete fin part with one press

Technical Parameter

| ITEM | DATA |

| Hole array | 25*22mm |

| Fin width | customized |

| Overall dimension | 105*24*22cm |

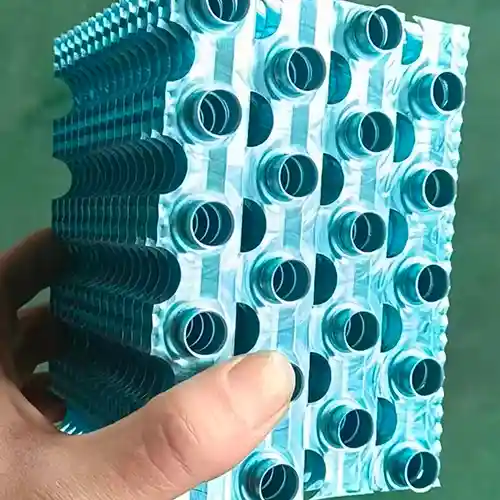

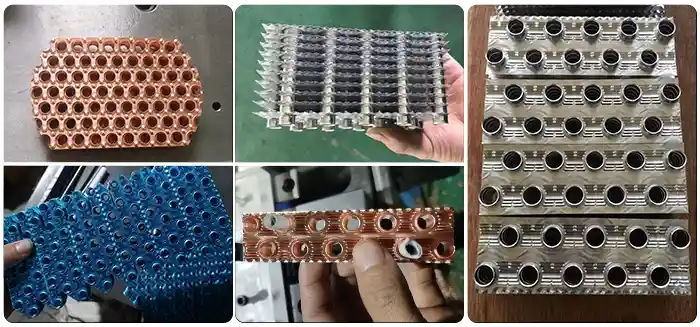

| Hole diameter | φ8mm φ9.53mm φ12.87mm customized |

| OTHER DATA | customized |

Progressive die stamping advantage

1, stamping mold can achieve high-speed production, thereby improving production efficiency. In the production of foil for condensers and heat exchangers, the progressive die can produce a large number of aluminum foil products in a short period of time, thereby improving production efficiency.

The fastest production speed is 300 times per minute, while traditional handmade methods require a longer time.

2, Progressive die stamping molds can achieve high-precision production, thereby improving product quality. Due to the automated production process of stamping molds, it is possible to ensure extremely high accuracy in the size and shape of foil products.

In addition, the progressive die can be customized according to different needs to adapt to different production needs and aluminum foil product specifications. This customized design can make the mold more suitable for producing specific aluminum foil products, thereby improving product quality and production efficiency.

3, Progressive die stamping molds can save production costs and improve the competitiveness of enterprises. By using this mold, enterprises can achieve efficient and high-precision aluminum foil production, thereby improving production efficiency and product quality.

In addition, the durability of stamping die is high, which can extend the service life of the molds and thereby reduce production costs.

raw material

| Mold parts | Material |

| Big plate | EN C45 |

| Small plate | Cr12 Cr12MoV |

| Stamping needle | SKH55 SKD11 |

| Louver parts | SKH55 SKD11 |

| Guide pillar | SUJ2 |

| Mold Spring | 50CrVA |

progressive stamping die factory video

WHY CHOOSE US

- We produce all mold parts and effectively control the cost of molds, so our mold prices are very competitive

- Our team has an average working age of over 17 years in the field of mold production, so we can produce and customize any type of fin mold

- The factory has 3 large CNC machines and 5 high-precision wire-cutting machines, ensuring that the accuracy of each component can meet the expected requirements and ensuring the accuracy and quality of the progressive stamping die

- The factory covers an area of approximately 1000 square meters and can produce over 200 large condenser fin molds annually. This production capacity provides effective and timely delivery guarantees

wechat

wechat