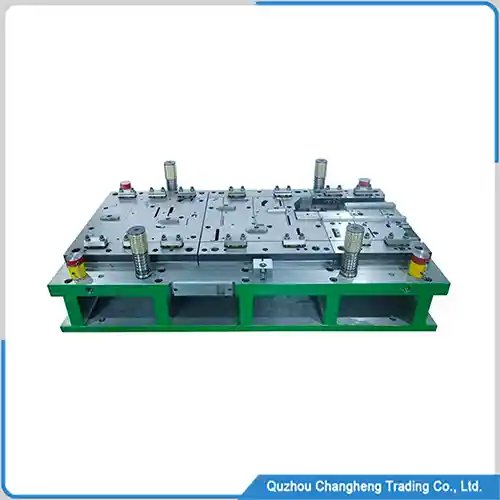

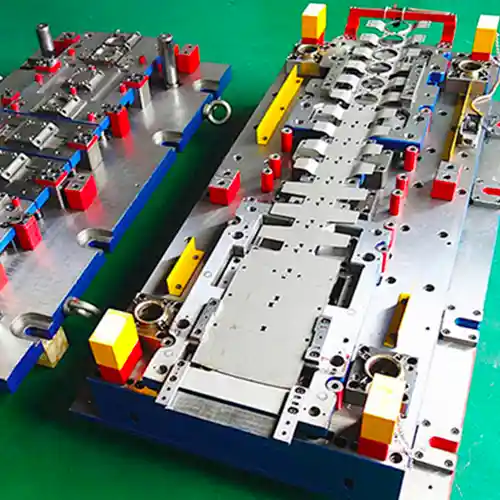

Mold Overview

The Progressive mold is a type of mold used in stamping production, mainly for mass production of parts, In this type of mold, the workpiece is processed one by one through each workstation in a certain order under the drive of the conveying device, and each workstation has an independent mold for corresponding stamping, bending, stretching and other operations.

Therefore, progressive molds can achieve continuous processing of workpieces through multiple processes, improving production efficiency.

The advantages of progressive mold

1, High production efficiency:

Progressive molds can achieve continuous and automatic production, greatly improving production efficiency.

2, High precision:

Due to the continuous production process of progressive molds, the dimensional and shape accuracy of the product can be guaranteed.

3, Material saving:

In the production process of progressive mold, the material utilization rate is high, reducing material waste.

4, Reduce labor intensity:

The production process of progressive molds is automated, reducing the labor intensity of workers.

5, Suitable for large-scale production:

Progressive molds are suitable for large-scale production and can reduce production costs.

progressive mold data

| No. | ITEM | DATA |

| 1 | Product materials: | iron, aluminum, copper, etc |

| 2 | Production type: | continuous |

| 3 | Mold type: | Stamping mold |

| 4 | Product shape: | Follow customer design |

| 5 | Mold Color: | default green |

| 6 | MOQ | 1 pcs |

Why choose our mold

- Accept customized parts of any type

- Mold engineers have rich design experience

- 80% of mold parts are manufactured in their own factories, effectively ensuring quality and timely delivery

- The price is very competitive

- Manufacturing molds can provide OEM production for customers, solving the problem of insufficient production capacity in your factory

progressive mold working video

Q & A

A: Of course, it can produce any type of sheet metal raw materials.

A: You can provide engineering drawings, 3D models, or samples.

A: Small size parts, stamping parts that can be produced on a large scale, these parts are all jobs that we excel in.

wechat

wechat