Product Overview

The progressive press tool are continuous manufacturing molds designed specifically for industrial heat exchangers, with the advantages of stable production, high efficiency, fast speed, and flexible size adjustment. They are widely used in modern industrial manufacturing.

This tool is suitable for producing various raw materials such as copper, aluminum, stainless steel 304, titanium alloy, etc., and can meet the needs of various industrial production.

The stamping tools we provide are compatible with installation on different brands of stamping machines, with simple operation and a stamping frequency of up to 500 times per minute.

progressive press tool application

- Mechanical radiator, which is a type of radiator installed in car engines.

- Household heat exchanger, which is a product for heating homes in winter.

- Air conditioning condensers, large outdoor machines for air conditioning require the installation of this large-sized condenser.

- Automotive evaporator, which is an evaporator installed on refrigerated cars.

- Industrial heat exchanger, which is also used in the industrial field, is characterized by its large size and high price.

- In other fields, our progressive press tool has many applications.

Technical Parameter

| ITEM | DATA |

| Appearance color | default yellow |

| Hole size | 3/8 ” 5/8” customized |

| Hole spacing | following design |

| Collar height | 1.5-8mm |

| Hole | 4-18 rows |

| Delivery time | 55 days |

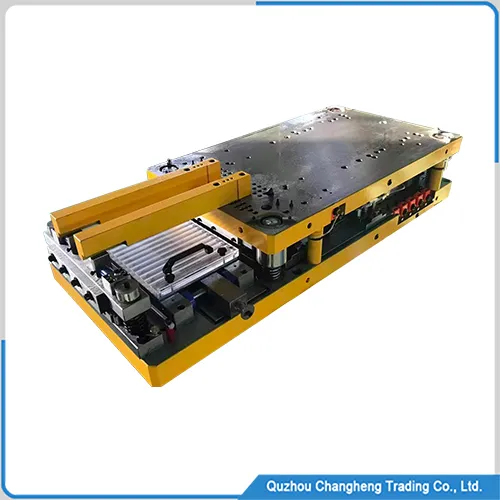

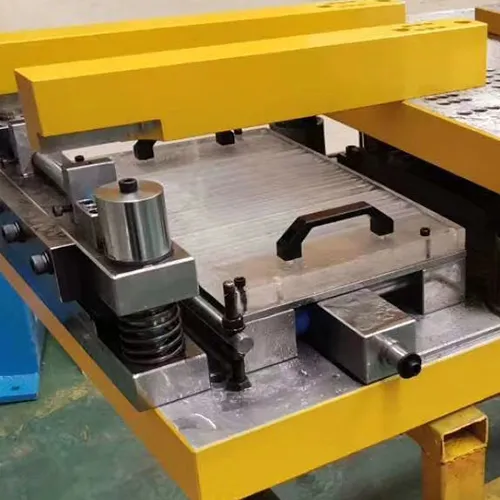

progressive press tool structure

This tool is indeed very advanced. Its large stamping mold integrates multiple independent small molds, each with specific functions, working together to achieve continuous production.

Most importantly, it also achieves automated cutting. When the punch reaches the preset number of stamping times, the sliding cylinder will automatically slide to the left, and the cutting blade will cut off the heat sink. The entire process is very fast and does not require manual supervision.

This design not only improves production efficiency but also reduces manual errors, which is very in line with the needs of the modern manufacturing industry.

Q & A

A: We customize this tool according to your requirements. You can provide technical details of your stamping machine and we will provide you with the best solution.

A: Our tools are customized, A tool with 12 rows of holes, usually measuring 1100*450*350mm in size.

A: Of course, it can produce fins in rows 6, 5, 4, 3, 2, 1.

wechat

wechat