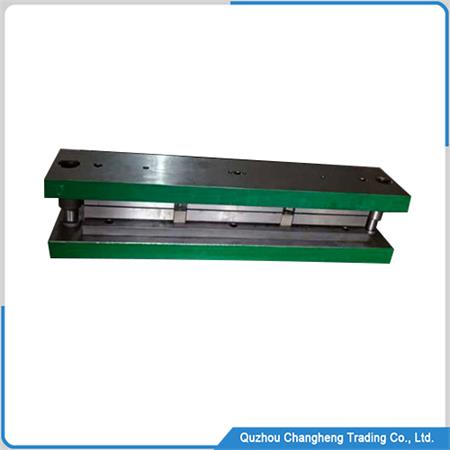

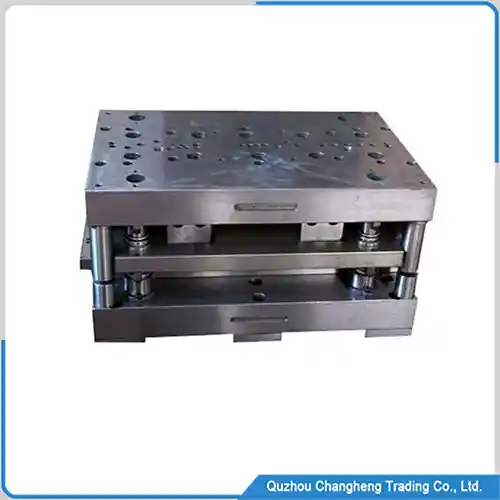

Stamping die outline

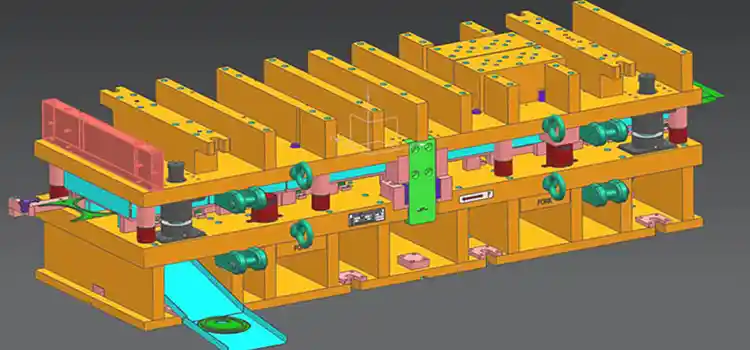

The progressive stamping die is a method of gradually manufacturing products by gradually manufacturing parts to form a complete product.

This technology can greatly improve production efficiency and product quality while reducing production costs and waste generation.

For early technology integration, our engineers utilized SolidWorks, CAD, UG, and other professional industrial applications

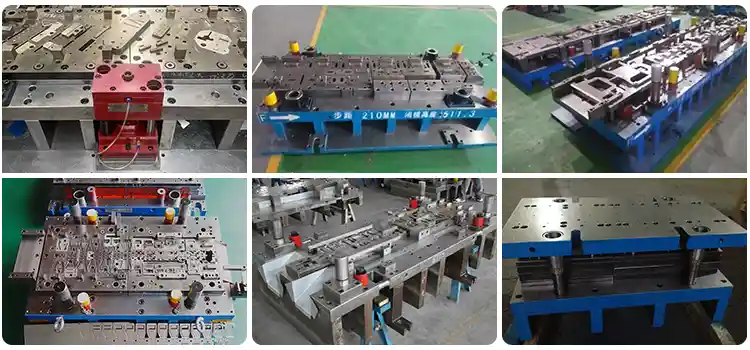

We allow progressive stamping die to be customized for a variety of metal components, including vehicle and motorcycle parts, hardware, everyday electrical components, etc.

| ITEM | DATA |

| Delivery time | 45 days |

| Formwork flatness | +/-0.01mm |

| Our Certificate | TS16949 CE ISO9001 |

| Die Material | MD40 MC53 SKH-9 SKD11 |

| Die part accuracy | +/-0.01mm |

| MOQ | 1 PCS |

| Die size | custom made |

Why choose us

- Provide a prompt response and a quotation for your design.

- Being an expert in the design, creation, and production of hardware part molds

- Capability for effective cost control and unexpected value-added services

- High-quality control with ongoing development, with no concerns regarding the use of progressive die and stamping

- A qualified design team, a precise mold-making machine, and mold-testing tools

progressive die-stamping video

Q & A

A: Sure, all of our Continuous stampings die will be put through testing in China, and samples will be shipped to your facility via express for inspection. Alternatively, you can hire a third party to check the goods at our factory.

A: Absolutely, we can offer free stock samples for both metal and plastic parts. Bespoke molds and mold components are unable to produce samples. Please be aware

A: The company’s internal papers are all within the system’s control, thus none can be automatically sent out. We won’t send the drawings to a third party without your consent. Please feel at ease.

A: Our mold warranty period is 12 months or 300’000 times of mold production

wechat

wechat