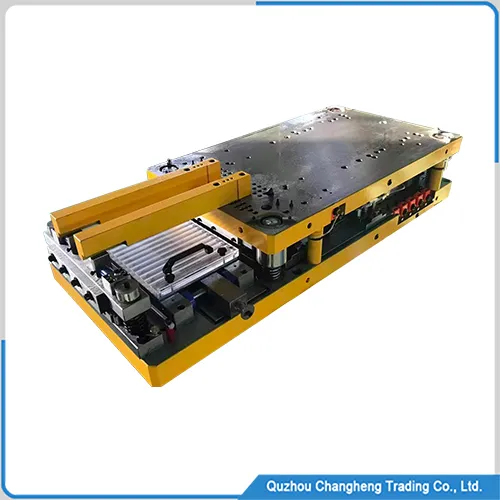

Product Description

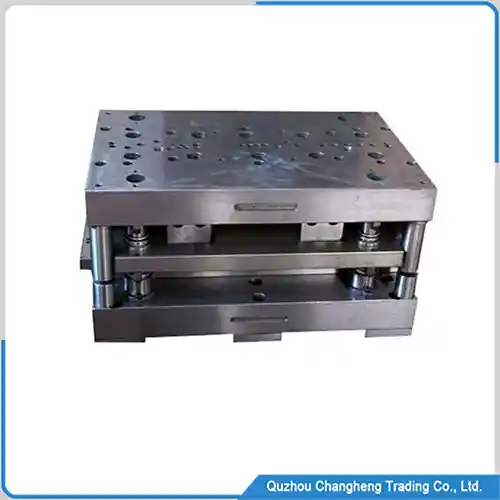

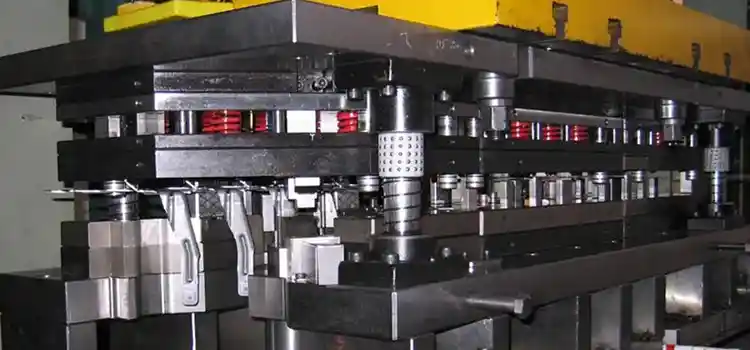

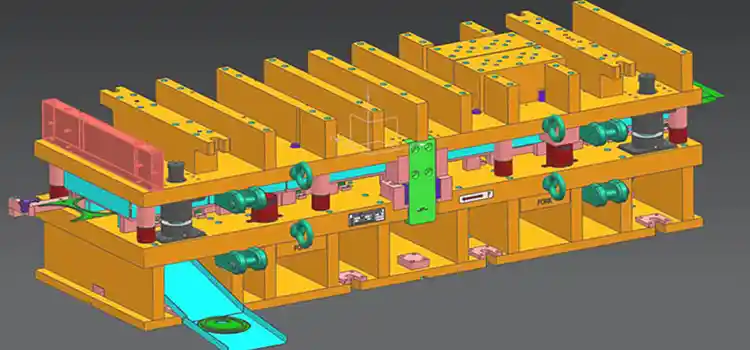

This progressive stamping die is an automatically produced metal mold pressed by multiple workstations simultaneously, each completing a separate step, achieving fully automated production.

It has the characteristics of fast production speed and stable size. Nowadays, many factories like stamping molds because they can effectively reduce manufacturing costs.

Advantages of progressive stamping dies

- raise productivity

This mold has been scientifically designed to produce a complete part with each press. Compared to a single press mold, its production capacity has increased exponentially

- cost reduction

Usually, this continuous mold has an automatic feeding device, eliminating the need for workers to supervise the machine and mold, effectively reducing labor costs.

- Reliable quality

This mold is made using high-precision machine tools to ensure the dimensions of the parts are met. Key components have vacuum quenching,

- Convenient maintenance

The parts of this mold have been independently design. When it wears out over long-term use, only a higher cost is need to replace it, greatly extending the mold’s overall service life.

Disadvantages of progressive stamping dies

- The price is high

Because the design of this mold is very complex, with multiple steps combined, manufacturing it requires high-precision machinery and technology. Compared to ordinary molds, it is very expensive.

- Longer delivery time

Because there are many parts in stamping molds, among which key parts require vacuum quenching treatment and important parts require high-precision manufacturing, their delivery time is relatively longer

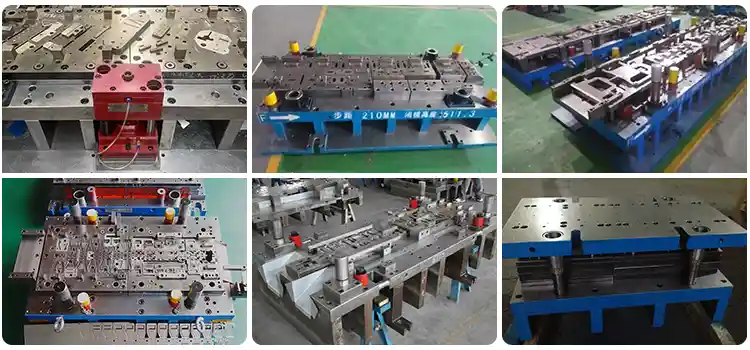

More stamping molds

Fin stamping die for sale

Fin Die Overview Fin stamping die play a crucial role in the HVAC fin stamping industry. They are not only a high-performance innovative tool, but also renowned for their excellent tolerance accuracy in the industry….

Condenser fin mold and Progressive die

Product Introduction The condenser fin mold is a tool for continuous high-speed production. It is a fully auto progressive mold tool that combines multiple molds with different functions. This mold is the main production tool…

progressive stamping dies Applications

With the upgrading of industry, people’s awareness of safety production has increased, and the application of this fully automatic stamping mold is becoming more and more widespread,

It is indispensable in some industrial parts that require large-scale production, such as automotive parts, hinges for doors and windows, and other hardware components.

We recommend that OEM factories prioritize using this progressive stamping die, which reduces production costs and ensures consistent part quality.

Progressive die-stamping working video

Q & A

A: Yes, we provide and customize a variety of continuous production molds, But our most professional field is the parts of automobile cooling systems, such as radiators, condensers, intercoolers, evaporators, etc.

A: It is better to provide part photos with dimensions, 3D design, or 2D design.

A: Because the design and manufacturing process of each mold is different, We haven’t seen your product pictures and designs, so we can’t give you an accurate delivery time, Usually our mold delivery time is 65-80 days

wechat

wechat